The Ultimate Guide to Blending for Plastics Processors

Walk through any plastics processing facility and you’ll hear the same frustrations: colorant costs that seem impossibly high, rejected parts from inconsistent blends, material inventory taking up valuable floor space, and operators spending hours each week manually measuring and mixing materials. These aren’t minor annoyances…they’re profit killers that compound with every production run.

The solution isn’t to simply work harder or buy more pre-compounded material. The answer is precision blending technology that puts you in complete control of your material costs, your product quality, and your bottom line.

This guide will walk you through everything you need to know about blending in plastics processing…from understanding why manual methods fail, to selecting the right equipment for your operation, to calculating real ROI from automated blending systems.

The Evolution of Blending: From Scoops to Precision Systems

In the early days of plastics processing, material handling was straightforward—and expensive. Most processors either bought pre-colored and specially formulated resins for each product they produced, or they measured out color concentrate and additives using a scoop and a scale. Drum tumblers were often used to tumble-mix the additive blend with virgin and regrind materials once it was manually created. Inaccuracies and inefficiencies were significant, but there was no alternative.

For simple mixing of regrind back into virgin material, processors attached proportioning valves to vacuum loaders and receivers to layer materials during loading in very rough proportions. As the industry grew and volumes increased, processors demanded equipment that would blend and mix ingredients in larger quantities with much greater accuracy.

The Volumetric Era

This need resulted in the development of the volumetric blender. In this device, materials were dispensed from their respective bins based on time, presuming a certain consistent flow rate for each ingredient. Screw augers ran beneath each material bin to move materials into a mixing chamber where all ingredients were combined. The augers were either different diameters, ran at different speeds, or ran for different durations to achieve the approximate desired proportional mix.

This need resulted in the development of the volumetric blender. In this device, materials were dispensed from their respective bins based on time, presuming a certain consistent flow rate for each ingredient. Screw augers ran beneath each material bin to move materials into a mixing chamber where all ingredients were combined. The augers were either different diameters, ran at different speeds, or ran for different durations to achieve the approximate desired proportional mix.

The most common customer complaint was inaccuracy of the blend, largely because of the inaccuracy of the main material quantities and the natural “pulsing” action of the augers. Metering accuracy was dependent upon the position of each auger when metering started and stopped, and undesirable vibration common with injection molding exaggerated the errors. Accurate and regular calibration of metering devices was required, but the calibration of volumetric devices is cumbersome, time-consuming, and fraught with the risk of human error.

The Gravimetric Revolution

In the higher material consumption world of continuous extrusion, solutions to these issues emerged with “loss-in-weight” gravimetric systems. In their original forms, these systems included supply bins for each material ingredient that were suspended on load cells so their weight could be individually monitored as they metered out each ingredient. These systems were complex and costly, but they were typical for extrusion lines capable of running high volumes for long, uninterrupted periods.

In the higher material consumption world of continuous extrusion, solutions to these issues emerged with “loss-in-weight” gravimetric systems. In their original forms, these systems included supply bins for each material ingredient that were suspended on load cells so their weight could be individually monitored as they metered out each ingredient. These systems were complex and costly, but they were typical for extrusion lines capable of running high volumes for long, uninterrupted periods.

Meanwhile, alternate methods utilizing a “gain-in-weight” principle into a single hopper on load cells were being developed along with blender controls that could monitor load cell status yet remain unaffected by typical vibrations. The result was a range of simplified, cost-effective, easily cleaned, and rugged gravimetric blenders suitable for injection molding and virtually any process.

The Breakthrough That Changed Everything

In the late 1980s, the plastics industry experienced a fundamental shift in blending technology. Processors didn’t need simpler volumetric feeders—they needed affordable gravimetric precision.

In the late 1980s, the plastics industry experienced a fundamental shift in blending technology. Processors didn’t need simpler volumetric feeders—they needed affordable gravimetric precision.

At the time, gravimetric systems existed but were prohibitively expensive, complex machines typically 6 by 6 feet and 8 feet high, with four hoppers and elaborate auger systems feeding a central chamber. Each ingredient required its own set of load cells, making these systems practical only for the highest-volume continuous extrusion operations. Injection molders, who faced constant vibration and needed frequent material changes, had no access to this level of precision.

The solution came through a revolutionary approach: gain-in-weight batch blending using a single set of load cells on a common weigh chamber. Instead of complex calibration procedures, the system weighed each ingredient as it was dispensed—making it self-correcting. Instead of being sensitive to vibration, sophisticated control algorithms filtered out interference while maintaining accuracy. The result was a compact, affordable, machine-mountable system that continuously self-corrects to deliver ±0.1% accuracy over multiple batches without calibration.

This breakthrough made gravimetric precision accessible to processors of all sizes. Today, these compact systems represent the industry standard for accurate, reliable blending across injection molding, extrusion, and blow molding operations worldwide.

The Impact

The affordability and ease of use of this new “weigh scale” blender caused gravimetric blending to expand rapidly. Nearly any processor could now afford this device that provided dramatically increased control and lowered operating costs through savings in colorants and other additives while eliminating the cumbersome calibration process. Processors could now confidently blend expensive additives that were formerly pre-compounded. They could add regrind without the risk of erratic melt behavior due to poor mixing. This provided dramatic cost savings and improved efficiency for plastics processors.

The affordability and ease of use of this new “weigh scale” blender caused gravimetric blending to expand rapidly. Nearly any processor could now afford this device that provided dramatically increased control and lowered operating costs through savings in colorants and other additives while eliminating the cumbersome calibration process. Processors could now confidently blend expensive additives that were formerly pre-compounded. They could add regrind without the risk of erratic melt behavior due to poor mixing. This provided dramatic cost savings and improved efficiency for plastics processors.

The Hidden Costs of Poor Blending

Many product performance issues that seem likely to be caused by improper drying or final processing actually stem from not knowing exactly what proportions of materials and additives are entering the process machine. Like any recipe, the correct ingredients must be measured carefully and mixed properly. If they’re not, the end result won’t be what’s expected…even if you process it exactly right.

Here are the most common issues that frequently stem directly from improper blending techniques.

- Substandard Product Quality

Uncontrolled use of regrind in the process is often traced to product performance failures. Regrind, if used at a higher level than prescribed by the material or product engineer, can result in premature product breakage and other performance issues.

Often, product testing creates a spike…tested products are returned to the granulator at one time and inadvertently end up overloading the regrind content of the product. The controlled introduction of regrind into the process cannot be left to chance or the inaccuracies of sub-standard mixing devices like proportioning valves or volumetric dosing devices. Critical quality products require critical blending equipment. - Inconsistent Color

Lack of color concentrate or poor mixing are typical culprits when colors are not consistent in plastic products. Inaccurate blending practices are usually to blame when colorant is not sufficiently introduced or blended. Many processors compensate for this possibility by “overdosing” color into the mix to ensure it’s amply distributed during processing. But that leads to runaway colorant costs. The best solution is to use automated equipment that meters colorant by weight and provides ample mixing prior to processing. These devices are designed to halt production if proper coloring is not possible due to a blockage or lack of material, and typically save thousands of dollars over time in colorant costs. - Runaway Additive Costs

Color concentrate and other additives, especially if custom compounded, can represent a significant expense if their use is not highly controlled. It’s common practice to “overdose” to assure an adequate color or property when lower-tech methods are used to introduce additives to the process. Overdosing is a very expensive waste of money and lacks the cost control essential to cost-effective molding or extruding. The use of an automated blender that meters precious additives consistently and then checks and corrects each batch by weight is key to keeping costs under control. - Excessive Labor Costs

Incorrect production of parts not only creates waste from rejected parts, but also the labor to deal with them. In addition, sub-standard mixing and blending equipment that requires frequent calibration and checking to assure consistent operation consumes too many labor hours while also introducing the element of human error. Consistency and lack of human interaction are best achieved by automated blending equipment that does not require calibration by using weight readings for every dosing. - Material Inventory Nightmares

Processors who purchase pre-compounded materials for every color and formulation they run face enormous inventory challenges. Each unique compound must be stored, tracked, and managed. If specifications change or a product is discontinued, you’re left with unusable material. This ties up cash flow and warehouse space while increasing the risk of using the wrong material in production.

Your Blending Options: From Worst to Best

Every processor has a choice in how to feed material to their process. Understanding the full spectrum of options, and their true costs, is essential to making the right decision for your operation.

Manual Mixing: Scoop and Weigh

The “scoop and weigh” method is labor intensive and typically a very inaccurate process, meaning you have no real control over your blending costs or accuracy. Human error runs rampant. Typically, colorants are used in higher quantities than necessary, leading to higher costs, but what if colorants or performance additives are shorted? Then product performance and appearance can vary greatly, leading to dissatisfaction among customers.

The “scoop and weigh” method is labor intensive and typically a very inaccurate process, meaning you have no real control over your blending costs or accuracy. Human error runs rampant. Typically, colorants are used in higher quantities than necessary, leading to higher costs, but what if colorants or performance additives are shorted? Then product performance and appearance can vary greatly, leading to dissatisfaction among customers.

Summary of manual mixing: Lowest initial investment, but labor intensive with high level of errors. No mixing unless a machine-mounted mixer is used. Results in excessive use of high-cost additives, poor quality control, high reject rates, and customer dissatisfaction. Manual procedures have no place in a modern factory.

Pre-Mixed and Custom Compounded Materials

Purchasing all materials pre-mixed or custom compounded is not only costly, but you’re putting the blending of your ingredients into the hands of a supplier over whom you have no control. Typically, you’re investing in high volumes of a number of unique materials that require extensive inventory space and record keeping. Changes in your process or material needs require extensive planning and testing of revised material formulations.

Purchasing all materials pre-mixed or custom compounded is not only costly, but you’re putting the blending of your ingredients into the hands of a supplier over whom you have no control. Typically, you’re investing in high volumes of a number of unique materials that require extensive inventory space and record keeping. Changes in your process or material needs require extensive planning and testing of revised material formulations.

Summary of pre-compounded material: No equipment investment, but highest material cost and highest level of material inventory. Ingredient blending is out of your control with high level of record-keeping required. Specification changes may leave you with unused material, and extensive testing is required for changed formulas. Keeping an inventory of unique formulations burdens your bottom line and your warehouse.

External Proportioning Valves (EPVs)

External proportioning valves (EPVs) are attached to self-contained loaders or to vacuum receivers in a central resin conveying system. They have two valves that are timed to open and close to layer materials into the loader or receiver as it’s loaded by vacuum. They’re typically used to introduce some approximate percentage of regrind into virgin material, but they’re actually best suited for simply allowing the consumption of regrind generated during processing. No real mixing takes place unless you install a separate mixer. This works if the appearance and properties of your end product are not critical and if your process can tolerate all of the regrind generated as it’s generated. But results of this type of “blending” are extremely erratic and should be avoided if quality control is important.

External proportioning valves (EPVs) are attached to self-contained loaders or to vacuum receivers in a central resin conveying system. They have two valves that are timed to open and close to layer materials into the loader or receiver as it’s loaded by vacuum. They’re typically used to introduce some approximate percentage of regrind into virgin material, but they’re actually best suited for simply allowing the consumption of regrind generated during processing. No real mixing takes place unless you install a separate mixer. This works if the appearance and properties of your end product are not critical and if your process can tolerate all of the regrind generated as it’s generated. But results of this type of “blending” are extremely erratic and should be avoided if quality control is important.

Summary of external proportioning valves (EPVs): Low equipment investment. May be acceptable to introduce regrind if product quality and appearance are not critical. Timed material proportions are approximate with no mixing unless a machine-mounted mixer is used.

Volumetric Blenders

Volumetric blenders may consist of two or more volumetric feeders mounted over a bin with or without a mixer. Materials are metered based on time, presuming consistent flow rates. Each component of the blend must be calibrated to assure a working knowledge of volume-to-weight ratios for properly setting up the blender. Volumetric blenders are basically timing devices that assume a certain volume of an ingredient added over time will yield a certain weight in the mix. This is typically inaccurate to some degree. Using more virgin or more additives than necessary impacts product cost and quality while decreasing profitability.

Volumetric blenders may consist of two or more volumetric feeders mounted over a bin with or without a mixer. Materials are metered based on time, presuming consistent flow rates. Each component of the blend must be calibrated to assure a working knowledge of volume-to-weight ratios for properly setting up the blender. Volumetric blenders are basically timing devices that assume a certain volume of an ingredient added over time will yield a certain weight in the mix. This is typically inaccurate to some degree. Using more virgin or more additives than necessary impacts product cost and quality while decreasing profitability.

Summary of volumetric blending: High investment considering its marginal accuracy. Depends on timed dispensing of free-flowing materials. Increased labor costs due to tweaking of dispense rates. Relatively low accuracy with poor control over material costs and higher reject rates. May be useable where product quality is not critical.

Gravimetric Blenders: The Precision Standard

Gravimetric blenders maintain blend accuracy to within ±0.1% by weight over time through continuous self-correction, so you can rest assured that ingredient proportions are uniform. Once set up and the recipe is entered, most gravimetric blenders automatically calibrate and run “hands-free” to ensure proper proportions and mixing of ingredients. Advanced controls allow complete documentation of the blending process as a further level of quality control. This technology, pioneered by Maguire Products in 1989 and refined continuously since, represents over three decades of solving real processor problems with intelligent, simple solutions.

Gravimetric blenders maintain blend accuracy to within ±0.1% by weight over time through continuous self-correction, so you can rest assured that ingredient proportions are uniform. Once set up and the recipe is entered, most gravimetric blenders automatically calibrate and run “hands-free” to ensure proper proportions and mixing of ingredients. Advanced controls allow complete documentation of the blending process as a further level of quality control. This technology, pioneered by Maguire Products in 1989 and refined continuously since, represents over three decades of solving real processor problems with intelligent, simple solutions.

Summary of gravimetric blending: Highest initial cost, but quick recovery of investment. Hands-free operation reduces labor costs. Gravimetric dispensing within ±0.1% by weight provides significant reduction of additive costs, increased product quality and customer satisfaction, faster changeover times with removable hoppers, and machine-mount units that reduce floor congestion. Advanced controls provide complete documentation.

How Gravimetric Blending Works

Understanding the technology behind gravimetric blending helps explain why it delivers such superior results compared to volumetric methods or manual processes.

The Gain-in-Weight Principle

Batch gravimetric blenders use a “gain-in-weight” approach where materials are metered one at a time into a common weighed chamber equipped with load cells. This is fundamentally different from continuous “loss-in-weight” systems that require a separate set of load cells for each ingredient bin.

Batch gravimetric blenders use a “gain-in-weight” approach where materials are metered one at a time into a common weighed chamber equipped with load cells. This is fundamentally different from continuous “loss-in-weight” systems that require a separate set of load cells for each ingredient bin.

As each material is metered and deposited into the weighing chamber, its specific weight gain is sensed and calculated as part of the desired blend. Any inaccuracy is noted and the control modifies metering accordingly on the next metering cycle. Several metering cycles are typically included in each batch of blended material, so as time goes on, the blender actually becomes more accurate and self-corrects continuously throughout its operation. This continuous self-correction typically achieves specification within approximately ten batches as the system adjusts for material variations.

The materials are then discharged from the weigh bin into a mixing chamber, which is integrated into the system. There, the blend is homogenized continuously until use or to a specification set by the processor.

Metering Devices for Different Materials

The batch blender provides a metering method for all materials in the blend, but unlike continuous blenders, the batch system uses metering devices better suited to the nature and volume of each ingredient. This modularity is key to its versatility.

Typical metering devices include:

- Timed flapper or plunger-style valves for larger volumes

- Rotating augers for consistent medium-volume dispensing

- Minute metering corner valves that can trickle in tiny quantities at highly controlled and very repeatable rates

- Specialized feeders for wood flour, powders, and difficult-to-meter materials

Many batch blenders feature modular design that allows the manufacturer or even the processor to freely select and change the metering devices based on the changing needs of their particular blending task.

Vibration Immunity

![]() One of the key innovations in batch gravimetric blenders is sophisticated control logic that takes numerous weight readings and eliminates readings affected by vibration, then averages the remainder for extremely accurate weight monitoring. This advancement made gravimetric blending practical for injection molding environments where machine vibration had previously been a barrier.

One of the key innovations in batch gravimetric blenders is sophisticated control logic that takes numerous weight readings and eliminates readings affected by vibration, then averages the remainder for extremely accurate weight monitoring. This advancement made gravimetric blending practical for injection molding environments where machine vibration had previously been a barrier.

No Calibration Required

![]() Because each dose of material is weighed as a part of normal operation, the blender automatically provides its own form of “catch and weigh” as a normal part of each blending cycle. As a result, the user can directly input specific weight or ratio percentage settings into the control with no translation into time settings. Operation, although complex inside the control, is actually significantly simpler for the user.

Because each dose of material is weighed as a part of normal operation, the blender automatically provides its own form of “catch and weigh” as a normal part of each blending cycle. As a result, the user can directly input specific weight or ratio percentage settings into the control with no translation into time settings. Operation, although complex inside the control, is actually significantly simpler for the user.

The Business Case for Gravimetric Blending

Just about every processor can benefit from investing in blending equipment. Each of the following applications can provide rapid return on investment for any processor wanting to improve costs and quality.

Simple Regrind with Virgin Material Mix

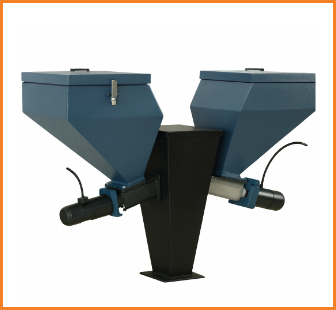

![]() Processors employing so-called proportioning valves, commonly used to layer regrind with virgin material while loading, are not blending but simply timing the irregular flow of regrind and virgin material. There is no real measuring nor real mixing, so some products end up with more regrind and some with less, and you may use more or less virgin than you want. That means you have no control over costs nor the quality of the product being produced. Even a simple two-component gravimetric blender can pay for itself quickly in this application.

Processors employing so-called proportioning valves, commonly used to layer regrind with virgin material while loading, are not blending but simply timing the irregular flow of regrind and virgin material. There is no real measuring nor real mixing, so some products end up with more regrind and some with less, and you may use more or less virgin than you want. That means you have no control over costs nor the quality of the product being produced. Even a simple two-component gravimetric blender can pay for itself quickly in this application.

In-House Coloring of Virgin Material

![]() If you process the same resin or resins every day but just in different colors, consider what your savings might be if you could meter the exact amount of various colors into your virgin material on demand. You could reduce your material inventory and purchase your natural resin in bulk, reducing material costs. You could also gravimetrically blend your regrind back in while processing to reduce your consumption of colorants. This scenario plays out repeatedly with processors who have gotten payback on their gravimetric blenders in a matter of months.

If you process the same resin or resins every day but just in different colors, consider what your savings might be if you could meter the exact amount of various colors into your virgin material on demand. You could reduce your material inventory and purchase your natural resin in bulk, reducing material costs. You could also gravimetrically blend your regrind back in while processing to reduce your consumption of colorants. This scenario plays out repeatedly with processors who have gotten payback on their gravimetric blenders in a matter of months.

Tracking Material and Additive Costs

![]() As refined as any manual blending process may be, real control over material consumption and real record keeping are typically left to chance with hopes for careful adherence to procedures. In today’s competitive world, simply hoping that humans always follow procedures is not good enough. The use of true gravimetric equipment that will not only flawlessly perform highly accurate blending functions day in and day out, but also keep track of all material consumption is, in itself, payback for the expenditure. Since every material—virgin, regrind, additives—is actually weighed as part of the gravimetric blending process, reports may be readily summoned that accurately track consumption and can even alert you to re-order points for your supplies. For the savvy processor, this can be accommodated plant-wide or even per job for true ROI reporting.

As refined as any manual blending process may be, real control over material consumption and real record keeping are typically left to chance with hopes for careful adherence to procedures. In today’s competitive world, simply hoping that humans always follow procedures is not good enough. The use of true gravimetric equipment that will not only flawlessly perform highly accurate blending functions day in and day out, but also keep track of all material consumption is, in itself, payback for the expenditure. Since every material—virgin, regrind, additives—is actually weighed as part of the gravimetric blending process, reports may be readily summoned that accurately track consumption and can even alert you to re-order points for your supplies. For the savvy processor, this can be accommodated plant-wide or even per job for true ROI reporting.

Assuring Product Quality

![]() Blending is not only an efficiency to reduce colorant costs and simplify plant processes, but for many processors and many products, highly accurate blending is the key to assuring product performance. Controlling the level of regrind in a critical component can affect not only color matching but also the strength or weakness of a part. The common mistake of overdosing color additive to assure adequate color matching not only creates unnecessary expense but can also affect the properties of the product. Wire manufacturers must be concerned about “sparking out” of their wire products from excess colorant. Many processors realize that excess color can change the magnetic or electrical properties of their products. The ability to show customers reports on actual material versus additive content by weight in every product is very compelling.

Blending is not only an efficiency to reduce colorant costs and simplify plant processes, but for many processors and many products, highly accurate blending is the key to assuring product performance. Controlling the level of regrind in a critical component can affect not only color matching but also the strength or weakness of a part. The common mistake of overdosing color additive to assure adequate color matching not only creates unnecessary expense but can also affect the properties of the product. Wire manufacturers must be concerned about “sparking out” of their wire products from excess colorant. Many processors realize that excess color can change the magnetic or electrical properties of their products. The ability to show customers reports on actual material versus additive content by weight in every product is very compelling.

Staying Flexible for Varying Feedstock Supplies

![]() In the still very new reclaim product marketplace, a consistent supply of feedstock cannot be assured and processors must be ready to make rapid formulaic changes to accommodate what is available or no longer available. Varying supplies of wood flour, regrind, flake, and other recycled content are often seized upon to be included in products that boast recycle content. Processors need equipment that can be quickly re-aligned for a changing feedstock supply. Gravimetric blenders are typically huge problem solvers for this class of processor with their ability to not only permit simple entry of new recipes but also retain past recipes that can be called upon to be run again. The fact that the blender is actually weighing all of the ingredients in each mix reduces the engineering strain of complex calculations and no calibration is required.

In the still very new reclaim product marketplace, a consistent supply of feedstock cannot be assured and processors must be ready to make rapid formulaic changes to accommodate what is available or no longer available. Varying supplies of wood flour, regrind, flake, and other recycled content are often seized upon to be included in products that boast recycle content. Processors need equipment that can be quickly re-aligned for a changing feedstock supply. Gravimetric blenders are typically huge problem solvers for this class of processor with their ability to not only permit simple entry of new recipes but also retain past recipes that can be called upon to be run again. The fact that the blender is actually weighing all of the ingredients in each mix reduces the engineering strain of complex calculations and no calibration is required.

Multi-Ingredient Processing Demands

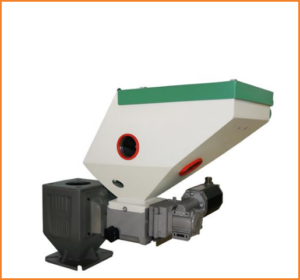

![]() Sometimes certain processors require blending of up to 12 ingredients with throughputs up to 8,000 pounds per hour. In the past, this would represent a truly unusual blender equipped with an array of feeders and accessories to accurately feed a variety of raw materials like pellets, wood flour, powders, colorants, and additives for weather-ability, flexibility, and a host of other properties. These capabilities are now available in modular, standardized designs ready to serve high-volume operations.

Sometimes certain processors require blending of up to 12 ingredients with throughputs up to 8,000 pounds per hour. In the past, this would represent a truly unusual blender equipped with an array of feeders and accessories to accurately feed a variety of raw materials like pellets, wood flour, powders, colorants, and additives for weather-ability, flexibility, and a host of other properties. These capabilities are now available in modular, standardized designs ready to serve high-volume operations.

Implementation Options

Automatic multi-component blenders are typically installed in four common configurations, each with distinct advantages depending on your operation.

- On the Process Machine Installation

In these installations, the blender is integrated into the process flow directly, and all materials entering the machine throat flow through the blender. This type of installation provides the greatest mix integrity since blended materials have no opportunity to separate between the blending operation and the process. Typically, gravity provides the flow to the process and usually the demand for blending is created by the process flow itself via a sensor in the mix chamber of the blender.

The blender frame is installed onto the throat of the process via an adaptor plate that matches the blender base to the processing machine throat bolt pattern. Since the blender and its associated loading equipment and other peripherals can be heavy, the integrity of this installation is critical to assure the structural security of the final installation.

- Beside the Process Machine Installation

Processors who frequently change colors or materials often benefit by placing the blender beside the processing machine instead of on it. The blender remains fully serviceable at floor level and a conveying system transfers the blended material to the machine throat. In some cases, the machine throat is not optimum for the location of equipment and a beside-the-process location is best.

The blender is mounted on a floor stand optimized for the blender and equipped with a material take-off box for conveying the blend. A flow regulator valve is included beneath the blender to assure sufficient mix time prior to the blended material free-falling into the take-off box.

- Mobile Blending Installations

For maximum flexibility, making the blender mobile on a wheeled frame makes the most sense in many cases. Only small to medium blenders are candidates for this feature. The blender is mounted on a frame similar to beside-the-process installations but equipped with casters, allowing the blender to be wheeled as needed to serve another processing machine, to be serviced or cleaned.

- Central Blending Installations

Using a single blender to serve the needs of multiple processing machines is an approach often used by captive molders or any processor running the same blend for multiple products. In these installations, the blender is located in a central area and either connected to each end-use machine by a material conveying system or provides a supply of material to storage vessels that can be transported as needed to the process machines.

Central blenders are often larger models providing higher volumes of blended materials to serve the demands of several process machines. Frequently, processors choose to centralize all of the blenders required for their operation and place them in a centralized location for easy material supply and material change operations. In these cases, dedicated personnel can be placed in charge of all blending and material change operations for the entire plant.

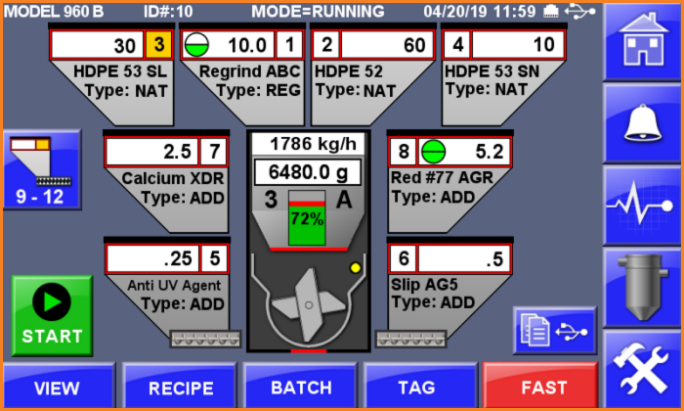

Modern Control Technology

The impressive advancements in control technology have not been overlooked in the latest generations of controls for automatic blenders. Acknowledging that the dialog between operators and machines that blend resins and additives can be confusing, blender manufacturers have strived to reduce the inputs, computations, and specialized knowledge required by the user to a minimum. Today’s blenders do the thinking for you.

Intuitive Interfaces

Earlier thumbwheel controls reduced the number of inputs required by allowing users to simply input the percentages of each ingredient desired. This interface methodology is intuitive and simple—literally, the control does the rest. Modern touch screen controls build on this simplicity by sporting images of thumbwheels that may be manipulated on the touch screen. User acceptance is instantaneous and the intimidation level is very low for everyday users. Yet the same screen can convert to more sophisticated use with a simple touch of another area of the screen.

Advanced Features

Modern blender controls are loaded with features:

- Recipe storage for quick changeovers

- Multiple user access levels (operator vs. engineering)

- Material consumption tracking and reports

- Re-order point alerts

- Ethernet, USB, or serial communications for data integration

- Multiple language support

- Password protection

Documentation and Traceability

Since every material—virgin, regrind, additives—is actually weighed as part of the gravimetric blending process, rich reports detailing yield results are commonly available and constantly updated with each new blending batch. For processors in regulated industries or those serving customers with strict documentation requirements, this level of traceability is invaluable.

At Novatec, We Understand What's At Stake

For plastics processors, material costs often represent 60-80% of total production costs. Even small improvements in material efficiency translate directly to your bottom line. But it’s not just about cost…it’s about control. Control over your formulations, your quality, your inventory, and ultimately your profitability.

As part of the Maguire family of companies, Novatec brings you the same gravimetric blending technology that Steve Maguire pioneered in 1989…the innovation that transformed affordable precision from impossible to standard. With over 60,000 systems operating worldwide, these aren’t experimental solutions. They’re proven technology, continuously refined over three decades based on real-world processor feedback and constant innovation.

Through our association with Maguire Products, Novatec brings you blending systems designed and manufactured by Maguire—the most extensive line of reliable blenders and feeders in the world, from compact on-machine dosers for single additives to high-capacity multi-ingredient systems processing 8,000 pounds per hour. Every system is built on the same core principle: weighing ingredients as they’re dispensed to continuously self-correct and deliver ±0.1% accuracy over time without calibration, without guesswork, and without waste.

Our Approach to Blending

We believe blending equipment should make your job easier, not more complicated. That’s why our systems feature:

- Modular Design for Maximum Flexibility

Whether you’re blending two ingredients or twelve, pellets or powders, our modular approach lets you configure the exact metering devices you need for your specific materials. Removable hoppers and interchangeable dosing units mean quick changeovers and easy cleaning—not hours of downtime. - Intuitive Controls That Anyone Can Use

From thumbwheel simplicity to advanced touch screens with complete recipe management, our controls are designed for the people who use them every day. Input your desired percentages, and the system handles the rest—automatically adjusting for material variations, tracking consumption, and documenting every batch. - True Gravimetric Precision

Our gain-in-weight batch systems use a single set of load cells on the common weighing chamber, making them simpler and more reliable than complex loss-in-weight designs. Sophisticated vibration-filtering algorithms make them perfect for injection molding environments while maintaining ±0.1% accuracy over time through continuous batch-to-batch correction. - Comprehensive Material Handling

Blending doesn’t exist in isolation. Our systems integrate seamlessly with your existing conveying and drying equipment, whether you’re running a central system or standalone machines. We understand material flow from source to process because we design complete resin handling solutions. - Complete Support and Service

When you choose Novatec blending systems, you’re not just buying equipment—you’re gaining a partner who understands your operation. Our technical support team includes specialists who’ve worked in plastics processing facilities and understand the real-world challenges you face. We’re available when you need us, whether that’s during installation, optimization, or years down the road when you’re expanding capacity or changing materials.

The Right Solution for Your Operation

No two processing operations are identical, which is why we offer blending solutions spanning the full spectrum of applications:

- Small-Scale Dosing

Single-ingredient dosers for machine-throat mounting deliver precise colorant or additive metering for processors who need accuracy without the complexity of multi-component systems. - Standard Gravimetric Blenders

Two to six component systems for injection molding and extrusion operations, available in machine-mount or floor-stand configurations with throughputs from a few pounds per hour to several hundred. - High-Capacity Multi-Ingredient Systems

Large-volume blenders handling up to twelve ingredients with throughputs exceeding 8,000 pounds per hour for demanding extrusion operations, compounding, and products with high recycled content. - Mobile and Central Configurations

Flexible installations including wheeled carts for multi-machine service and centralized systems for consistent blends across multiple production lines.

Proven Results

Processors who’ve switched to gravimetric blending consistently report:

- 20-40% reduction in colorant and additive consumption by eliminating overdosing

- Payback periods of 6-18 months depending on throughput and material costs

- Near-zero rejects from color or property inconsistencies

- Dramatic reduction in material inventory and associated carrying costs

- Complete material consumption documentation for cost accounting and quality systems

Ready To Take Control Of Your Material Costs?

The decision to invest in gravimetric blending equipment isn’t just about buying machinery…it’s about taking control of one of your largest operating expenses while simultaneously improving product quality and operational efficiency.

If you’re still using manual methods, proportioning valves, or volumetric systems, you’re leaving money on the table with every production run. The question isn’t whether precision blending will pay for itself, but how quickly.

We talk to processors like you every single day about specific blending challenges…whether it’s getting regrind consumption under control, eliminating color streaking, or just figuring out why additive costs keep climbing. Every operation is different, and we’d love to understand yours.

Give us a holler or reach out on the form below to start a conversation about your blending needs. Whether you’re running a single machine or a multi-line facility, processing commodity resins or specialty compounds, we’ll help you figure out the right solution for your operation.

No sales pitch. No pressure. Just a conversation about what’s possible when you have complete control over your material costs and product quality.

Ask The Expert Blending

"*" indicates required fields