The Ultimate Guide to Feeding for Plastics Processors

Ask processors about their biggest operational headaches, and color dosing inevitably makes the list. The numbers tell the story: colorant costs climbing year after year, rejected parts piling up from color inconsistencies, operators burning hours every week on calibration procedures that never quite work. And underneath it all, a gnawing question—are we over-dosing just to be safe?

The answer is usually yes. Most processors are.

Here’s the uncomfortable truth: traditional volumetric feeders weren’t built for the precision today’s quality standards demand. They were designed for an era when “close enough” was acceptable. Those days are gone.

Every over-dosed shot melts money in your barrel. Every color-mismatched part is profit you’ll never see again. And the worst part? Most processors know they’re wasting material but don’t know how to stop.

But there’s a better way. Precision feeding technology exists that can eliminate calibration, reduce colorant consumption by 30% or more, and give you complete control over every gram of material entering your process.

This guide will walk you through everything you need to know about feeding in plastics processing—from understanding why volumetric methods fall short, to selecting the right equipment for your operation, to calculating real ROI from gravimetric feeding systems.

How We Got Here: The Feeding Problem Nobody Solved

In the early days of plastics processing, adding color or additives to virgin material was straightforward—and wasteful. Most processors either bought pre-colored materials for every product they made, or they manually measured colorant by weight and dumped it into the material flow, hoping for adequate mixing. Consistency was poor, waste was high, but there were no alternatives.

As volumes increased and product specifications tightened, the industry demanded better solutions for introducing minor ingredients into the material stream.

Manual Dosing: The Starting Point

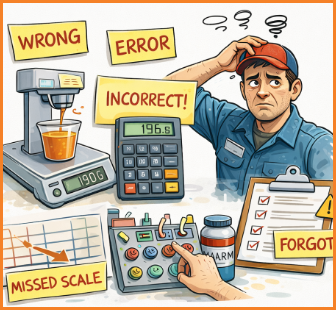

The simplest approach was manual dosing—measuring colorant or additives by hand and introducing them into the material flow. A scoop, a scale, careful attention, and hope for the best. The problems were obvious: human error, inconsistent dosing, no real mixing, and significant waste from over-dosing “to be sure” enough additive made it into every part.

The simplest approach was manual dosing—measuring colorant or additives by hand and introducing them into the material flow. A scoop, a scale, careful attention, and hope for the best. The problems were obvious: human error, inconsistent dosing, no real mixing, and significant waste from over-dosing “to be sure” enough additive made it into every part.

Manual dosing worked when volumes were low and specifications were loose. But as production ramped up and customers demanded tighter tolerances, processors needed automated solutions.

The Volumetric Era

The first automated feeding devices were volumetric dosers—simple machines that used a rotating auger to meter material based on time and volume. The concept was elegant: the space between auger flights represented a known volume, and by calibrating the relationship between that volume and the actual weight of material, processors could dose at a predictable rate.

The first automated feeding devices were volumetric dosers—simple machines that used a rotating auger to meter material based on time and volume. The concept was elegant: the space between auger flights represented a known volume, and by calibrating the relationship between that volume and the actual weight of material, processors could dose at a predictable rate.

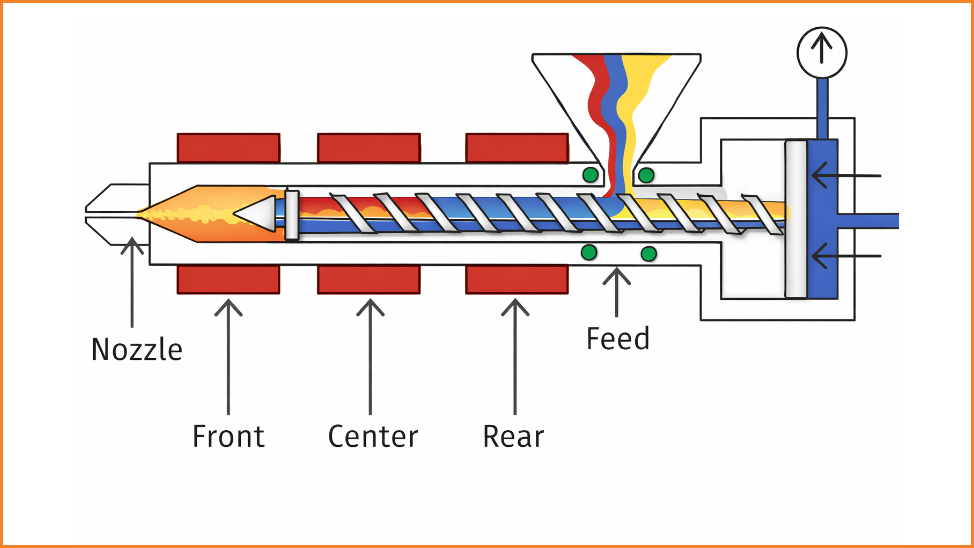

These devices mounted directly to the machine throat via an adaptor that created a void in the material flow, allowing the dosed additive to join the stream of base resin. A variable-speed DC motor controlled the auger rotation, and in injection molding applications, the doser synchronized with the press cycle to deliver a measured amount of colorant with each shot.

Volumetric dosing represented a major step forward from manual methods. But significant problems remained:

The Calibration Trap

Change colorants? Recalibrate. Switch additives? Recalibrate. New material lot arrives? Recalibrate.

Change colorants? Recalibrate. Switch additives? Recalibrate. New material lot arrives? Recalibrate.

The “catch and weigh” ritual became a fact of life: collect dosed material in a cup, weigh it on a scale, calculate how far off you are, twist some knobs, try again. For shops running multiple colors across multiple machines, calibration became a part-time job. And every calibration cycle introduced new opportunities for operator error—wrong calculations, misread scales, forgotten adjustments.

Accuracy Was Fundamentally Limited

Volumetric feeders assumed a consistent relationship between auger volume and material weight. But that assumption broke down constantly. As colorant levels dropped in the supply hopper, material flow changed. If materials bridged or didn’t flow smoothly, the auger might move air instead of material. If bulk density varied between batches of the same colorant, the weight-per-revolution changed. The feeder had no way to detect these problems—it simply kept rotating at the programmed speed, delivering whatever happened to fall into the auger flights.

Volumetric feeders assumed a consistent relationship between auger volume and material weight. But that assumption broke down constantly. As colorant levels dropped in the supply hopper, material flow changed. If materials bridged or didn’t flow smoothly, the auger might move air instead of material. If bulk density varied between batches of the same colorant, the weight-per-revolution changed. The feeder had no way to detect these problems—it simply kept rotating at the programmed speed, delivering whatever happened to fall into the auger flights.

The result? Processors over-dosed “to be safe,” wasting expensive colorant to ensure minimum additive levels under all conditions. This safety margin added up quickly. Even small amounts of over-dosing—an extra 0.5% here, an extra 1% there—represented thousands of dollars in unnecessary material costs across a year of production.

Drift and Inconsistency

Early DC motors had speed control issues. They would drift as they operated, and when de-energized at cycle end, they often dribbled to a stop rather than stopping cleanly. This meant the actual dose varied shot-to-shot, even when settings remained constant. For applications where color consistency mattered, this variation showed up as visible color shifts from part to part.

Early DC motors had speed control issues. They would drift as they operated, and when de-energized at cycle end, they often dribbled to a stop rather than stopping cleanly. This meant the actual dose varied shot-to-shot, even when settings remained constant. For applications where color consistency mattered, this variation showed up as visible color shifts from part to part.

The Breakthrough: Stop Guessing, Start Weighing

The solution came from a simple insight: stop assuming what the auger is delivering, and start measuring it.

The solution came from a simple insight: stop assuming what the auger is delivering, and start measuring it.

Gravimetric feeders added load cells under the supply hopper and weight-based control logic. Instead of hoping the relationship between auger rotations and material weight stayed constant, the system tracked actual weight loss continuously during operation.

The concept was transformative: mount the supply hopper on load cells, monitor the loss-in-weight as material feeds, and automatically adjust auger speed to maintain the target dose. If bulk density changes, the system detects it immediately through weight readings and compensates. If material flow becomes erratic, load cells catch the variation and correct it. If the hopper runs low and material packs differently, the feeder adjusts automatically.

This single innovation dramatically reduced both major problems with volumetric feeding: frequent calibration procedures were minimized since the system weighed material continuously and made automatic adjustments, and accuracy improved dramatically because dosing was controlled by actual weight rather than assumed volume.

Today’s gravimetric feeders measure weight continuously—tracking every gram that leaves the hopper—and adjust auger speed in real-time to hit the target dose within ±0.2% accuracy. Process variations that would throw off a volumetric feeder get caught and corrected automatically. The system generates complete material usage records as a natural byproduct of operation, supporting both quality documentation and cost accounting.

What began as a solution to colorant waste became the foundation of modern precision feeding technology. Today’s gravimetric feeders deliver laboratory-grade accuracy in production environments, eliminating overdosing waste while ensuring consistent product quality.

Understanding Feeding Technology: Your Options

Every processor faces a choice in how to introduce additives and colorants to their process. Understanding the full spectrum of options—and their real costs—is essential to making the right decision.

Manual Dosing: Scoop and Hope

Manual methods represent the lowest equipment investment but the highest operational cost. An operator measures colorant by weight, dumps it into the material stream, and hopes for adequate mixing. Unless a separate mixer is installed, blending is minimal.

Manual methods represent the lowest equipment investment but the highest operational cost. An operator measures colorant by weight, dumps it into the material stream, and hopes for adequate mixing. Unless a separate mixer is installed, blending is minimal.

Summary: Lowest initial investment, but labor intensive with high error rates. Results in excessive use of expensive additives, poor quality control, high reject rates, and customer dissatisfaction. Manual dosing has no place in modern production environments.

Pre-Colored Compounds

Some processors avoid dosing equipment entirely by purchasing pre-colored materials. The material supplier handles all color compounding, and the processor simply molds or extrudes the finished product.

Some processors avoid dosing equipment entirely by purchasing pre-colored materials. The material supplier handles all color compounding, and the processor simply molds or extrudes the finished product.

The advantages are simplicity and consistency—no dosing equipment to maintain, no calibration procedures, no color dosing errors. But the costs are substantial: pre-colored materials command significant price premiums over natural resins, you’re locked into buying large minimums of each color, inventory carrying costs multiply, and any specification changes require extensive lead times for new material formulation and testing.

Summary: No equipment investment, but highest material costs and largest inventory commitment. Changes in specifications or colors may leave you with unusable material. Every color variation requires separate inventory management and warehouse space.

Volumetric Feeders

Volumetric feeders use an auger driven by a variable-speed motor to meter material based on time and volume. The relationship between auger flights (volume) and material weight is established through calibration, allowing the processor to dose at specific rates.

Volumetric feeders use an auger driven by a variable-speed motor to meter material based on time and volume. The relationship between auger flights (volume) and material weight is established through calibration, allowing the processor to dose at specific rates.

The advantages are simplicity and lower equipment cost compared to gravimetric systems. A DC motor, an auger, a supply hopper, and basic controls provide automated dosing directly at the machine throat.

The disadvantages are accuracy and the constant need for calibration. Volumetric feeders measure nothing during operation—they simply rotate the auger at a programmed speed and assume consistent material flow. Any change in bulk density, material flow, or hopper level that affects the actual weight dispensed goes undetected. The feeder has no feedback mechanism to catch these variations.

This leads to two problems: processors over-dose to ensure minimum additive levels under all conditions (wasting expensive colorant), or they experience color inconsistencies and quality problems when actual dosing falls below target.

Summary: Medium equipment investment, but marginal accuracy dependent on frequent calibration. Higher material costs from over-dosing, increased labor from calibration procedures, and limited quality control. May be acceptable where product appearance and properties aren’t critical.

Gravimetric Feeders

Gravimetric feeders use load cells to continuously monitor the loss-in-weight of the supply hopper, allowing real-time adjustment of auger speed to maintain precise dosing by actual weight—the same unit of measure on which specifications are based.

Gravimetric feeders use load cells to continuously monitor the loss-in-weight of the supply hopper, allowing real-time adjustment of auger speed to maintain precise dosing by actual weight—the same unit of measure on which specifications are based.

The supply hopper mounts on load cells that take constant weight readings. As the auger rotates and dispenses material, the system tracks exactly how much weight has been lost from the hopper. If the target calls for 50 grams per shot (or 50 grams per minute in extrusion), the feeder automatically adjusts auger speed to hit that target regardless of material variations.

After initial setup, the unit weighs each dose and makes automatic adjustments to ensure accuracy, dramatically reducing the frequent calibration cycles required by volumetric feeders. Periodic calibration ensures the load cells continue weighing correctly over time. Changes in bulk density, material flow, or processing rate are detected immediately through weight readings and corrected automatically. Sophisticated control algorithms filter out vibration interference—a critical capability for injection molding environments where machine vibration had historically made gravimetric systems impractical.

The result is ±0.2% accuracy through continuous self-correction, elimination of wasteful over-dosing, consistent product quality, and complete documentation of material usage for cost control and quality assurance.

Modern control systems make gravimetric feeding accessible to operations of all sizes. Touch-screen interfaces allow operators to input target dosing rates in intuitive percentage or weight-per-shot formats. The system handles all calculations and adjustments automatically.

Summary: Highest initial equipment cost, but rapid ROI from material savings and quality improvements. Hands-free operation reduces labor costs. Gravimetric dosing delivers significant reductions in additive costs, increased product quality and customer satisfaction, faster material changeovers, and complete material consumption documentation.

Liquid Color Pumps

Liquid colorants offer unique advantages for certain applications, particularly where excellent dispersion and low additive percentages are required. Liquid color is administered at the machine throat using peristaltic pumps that precisely meter liquid colorant into the material stream.

Liquid colorants offer unique advantages for certain applications, particularly where excellent dispersion and low additive percentages are required. Liquid color is administered at the machine throat using peristaltic pumps that precisely meter liquid colorant into the material stream.

The liquid colorant adheres to pellet surfaces and disperses effectively during the melting process. In many cases, the process itself provides adequate mixing without requiring separate mixing equipment.

Liquid color systems integrate directly with gravimetric controls to provide the same precision and documentation benefits as solid colorant feeding.

How Gravimetric Feeding Works

Understanding the technology behind gravimetric feeding helps explain why it delivers superior results compared to volumetric methods.

The Loss-in-Weight Principle

Gravimetric feeders operate on a loss-in-weight basis. The supply hopper sits on a set of load cells that continuously monitor its weight. As material feeds into the process, the system tracks exactly how much weight has been lost from the hopper. This provides real-time verification that the target amount of material has actually been dispensed.

Gravimetric feeders operate on a loss-in-weight basis. The supply hopper sits on a set of load cells that continuously monitor its weight. As material feeds into the process, the system tracks exactly how much weight has been lost from the hopper. This provides real-time verification that the target amount of material has actually been dispensed.

For injection molding applications, the feeder synchronizes with the press cycle. When the screw retracts (signaling a shot has been made), the feeder doses the programmed amount of colorant or additive. The loss-in-weight measurement confirms that the correct amount was dispensed. If the system detects any deviation, it automatically adjusts the next dose to compensate.

For extrusion applications (continuous processes), the feeder runs continuously and adjusts auger speed in real-time to maintain the target feed rate. If material flow changes or process speed varies, the feeder detects this through weight readings and responds immediately.

Vibration Immunity

One of the critical innovations in modern gravimetric feeding is sophisticated vibration filtering. Injection molding machines generate significant vibration—especially on fast-cycling presses—that historically made weight-based systems impractical.

One of the critical innovations in modern gravimetric feeding is sophisticated vibration filtering. Injection molding machines generate significant vibration—especially on fast-cycling presses—that historically made weight-based systems impractical.

Advanced control algorithms take numerous weight readings and filter out readings affected by vibration, averaging the remainder for extremely accurate weight monitoring. This breakthrough made gravimetric feeding practical for injection molding environments where vibration had previously been a barrier.

Automatic Self-Correction

Because the system weighs material continuously, small variations in bulk density, material flow, or hopper level are detected immediately and corrected automatically. The feeder adjusts auger speed or duration to hit the weight target regardless of material characteristics.

Because the system weighs material continuously, small variations in bulk density, material flow, or hopper level are detected immediately and corrected automatically. The feeder adjusts auger speed or duration to hit the weight target regardless of material characteristics.

This self-correction dramatically reduces the frequent manual “catch and weigh” calibration cycles required by volumetric feeders. While periodic calibration of the load cells is still needed, operators can change materials, adjust dosing rates, or modify process conditions without constant recalibration.

Complete Material Tracking

![]() Since every gram of material is weighed as part of normal operation, gravimetric feeders generate comprehensive data on material consumption. This information supports quality documentation requirements (ISO compliance, customer audits), enables accurate cost accounting by job or product, and helps identify opportunities for further material optimization.

Since every gram of material is weighed as part of normal operation, gravimetric feeders generate comprehensive data on material consumption. This information supports quality documentation requirements (ISO compliance, customer audits), enables accurate cost accounting by job or product, and helps identify opportunities for further material optimization.

When Feeding Makes Sense for Your Operation

Gravimetric feeding delivers benefits across a wide range of applications. Here are scenarios where feeding equipment can provide rapid return on investment:

- Simple Colorant Dosing

If your operation processes the same base resin but in different colors, a gravimetric feeder can eliminate the cost premium and inventory burden of pre-colored compounds. Purchase natural resin in bulk at lower cost, and dose colorant as needed for each production run.

This is the most common feeding application and often delivers payback in months. The savings from buying natural resin instead of pre-colored compounds, combined with the elimination of colorant over-dosing, quickly offset the equipment investment. Regrind Integration

Many processors use feeders to introduce regrind back into virgin material. Rather than investing in a full blending system (see our [LINK: Ultimate Guide to Blending] for multi-component applications), a simple feeder can accurately dose regrind at controlled percentages while maintaining product quality.

UV Stabilizers and Functional Additives

Products requiring UV protection, flame retardants, impact modifiers, or other functional additives benefit from precise dosing control. Over-dosing these additives wastes expensive materials, while under-dosing risks product performance failures and warranty claims.

High-Specification Applications

For processors serving industries with strict quality requirements—medical, automotive, electronics—gravimetric feeding provides the accuracy and documentation needed to meet specifications and maintain audit compliance. The complete material usage data generated by the feeder supports traceability requirements.

Just-in-Time Operations

Companies supplying customers on tight delivery schedules benefit from the operational flexibility feeding provides. Compounding at the machine throat eliminates the lead time associated with ordering pre-colored materials and allows rapid response to customer requirements.

Operations with Frequent Color Changes

If your production schedule involves frequent material or color changeovers, feeding equipment with removable supply hoppers enables quick changes without extended downtime. Many feeders allow multiple dosing units on a single throat adaptor for equipment redundancy or multi-additive dosing.

The Business Case for Gravimetric Feeding

The decision to invest in feeding equipment isn’t just about buying machinery—it’s about taking control of material costs while improving product quality and operational efficiency.

Reduced Material Consumption

Precise control over colorant and additive metering eliminates the wasteful over-dosing that’s common with volumetric feeders or manual methods. When you dose by actual weight rather than assumed volume, you use exactly the amount specified—no safety margin required.

For operations using expensive colorants or additives, this precision delivers substantial savings. A processor over-dosing colorant by just 0.5% across a year of production can easily waste tens of thousands of dollars. Multiply that across multiple machines and multiple products, and the waste becomes staggering.

Processors switching to gravimetric feeding consistently report 20-40% reductions in colorant and additive consumption. For high-volume operations, this material savings alone can deliver payback in less than twelve months—sometimes significantly shorter.

Improved Quality and Reduced Rejects

Consistent dosing means consistent product properties. Color stays uniform shot-to-shot and run-to-run. Additive levels remain within specification, ensuring product performance meets requirements.

This consistency reduces rejects from color mismatches or property variations. Every rejected part represents wasted material, wasted machine time, wasted labor, and potentially damaged customer relationships. Eliminating these rejects directly impacts profitability.

Operational Efficiency

Feeding at the machine throat eliminates the cost premiums associated with pre-colored compounds and frees processors from carrying extensive color inventories. Buy natural resin in bulk, dose colorant as needed, and respond quickly to customer requirements without waiting for material suppliers.

This operational streamlining is particularly valuable for companies serving customers on a just-in-time basis. The ability to change colors rapidly without material procurement delays can be a competitive differentiator.

Quality Assurance and Documentation

The material consumption data generated by gravimetric feeders supports quality documentation requirements for ISO operations, customer audits, and regulated industries. Having complete, automated records of exactly what materials went into every product provides traceability and accountability.

For processors serving high-specification markets—medical devices, automotive components, food packaging—this documentation capability can be as valuable as the material savings.

Expanded Automation Potential

The data generated by gravimetric controls can integrate into broader factory automation systems. Plant-wide monitoring of material consumption, predictive alerts for material reordering, and integration with cost accounting systems are all possible with modern feeding equipment.

Applications Across Plastics Processing

Gravimetric feeding delivers benefits across the full spectrum of plastics processing operations.

Injection Molding

Feeding equipment mounts directly to the machine throat and synchronizes with the press cycle. As the screw retracts, the feeder doses the programmed amount of colorant or additive into the material stream. Vibration-immune controls maintain accuracy even on fast-cycling presses.

Benefits include: precise colorant control, rapid color changeovers, reduced material waste, consistent part quality, and documentation of material usage per production run.

Extrusion (Film, Sheet, Profile, Pipe, Wire & Cable)

For continuous extrusion processes, gravimetric feeders run constantly and adjust dosing rates in real-time based on process speed. Some systems connect directly to the extruder drive to slave feeder speed to extrusion rate.

In wire and cable operations, precise control over insulation and jacketing compounds is critical for maintaining dimensional tolerances and electrical properties. Gravimetric feeding ensures consistent material delivery regardless of line speed variations.

Benefits include: quick payback from material savings, accurate processing of regrind, continuous material flow, tight control over expensive colorants and additives, and complete material consumption documentation.

Blow Molding

Blow molding applications benefit from consistent colorant dosing and accurate regrind integration. Since wall thickness variations can affect product performance and appearance, maintaining consistent material properties is critical.

Compounding

Compounding operations use gravimetric feeding to accurately meter minor ingredients into base polymer streams. The precision and documentation capabilities support quality requirements for producing consistent formulations.

Implementation Considerations

Installing feeding equipment requires attention to several key factors:

Throat Adaptors and Installation

Feeders mount to the machine throat via adaptors that support the supply hopper for base material, provide connection points for the feeding unit, create a void in the material flow for dosed additives to enter, and may accommodate mixing equipment below the feeder.

The adaptor design is critical for structural integrity, ease of calibration (on volumetric units), and proper material flow. Some mixing units can serve as the mounting point for feeders, eliminating the need for separate adaptors.

Supply Hopper Access

The feeder’s supply hopper receives daily attention for filling and cleaning, so it must be accessible. Plan ahead for automatic loading equipment if hand-filling will be impractical. Ensure adequate clearance between the additive hopper and the main material supply hopper—dimensional conflicts can require additional risers or alternative equipment selections.

Control Integration

For injection molding, the feeder control must connect to the press to receive signals for cycle synchronization. For extrusion, consider whether the feeder speed should slave to extruder speed for proportional dosing as line speed varies.

Modern touch-screen controls mount conveniently near the machine and provide intuitive interfaces for setting dosing rates, monitoring material consumption, and accessing documentation.

Multiple Feeders and Redundancy

Some installations benefit from multiple feeding units on a single throat adaptor—either for equipment redundancy (quick changeover between materials without downtime) or for dosing multiple additives simultaneously. Most systems allow independent operation of multiple feeders on common mounting points.

At Novatec, We Know What Feeding Costs You

Colorants run $15, $20, sometimes $30+ per pound—often ten times what you pay for base resin. A feeding system that over-doses by even half a percent can cost you thousands per machine per year. Multiply that across your facility and you’re looking at real money.

But the bigger cost isn’t the wasted colorant—it’s the parts you can’t ship. Color mismatches that force rework or scrap, customers who notice inconsistencies batch-to-batch, and the hours your team spends chasing problems that precision equipment would eliminate.

We bring you feeding systems built on decades of materials handling experience—technology designed to solve the actual problems processors face on production floors. Our gravimetric feeding systems deliver the accuracy, reliability, and ease of use that modern processing operations demand.

We believe feeding equipment should solve problems, not create them. That’s why our systems feature:

True Gravimetric Precision

Our loss-in-weight systems use load cells to continuously monitor material consumption, providing ±0.2% accuracy through automatic adjustments. Sophisticated vibration-filtering algorithms make our feeders ideal for injection molding environments while maintaining exceptional accuracy. Periodic calibration ensures the system continues weighing correctly over time.

Intuitive Controls That Work

From simple interfaces with essential functions to advanced touch-screens with recipe management and material tracking, our controls are designed for the people who use them every day. Input your target dosing rate, and the system handles the rest—automatically adjusting for material variations, tracking consumption, and documenting every dose.

Proven Reliability

With decades of experience in plastics processing environments, our feeding systems are built for the harsh realities of production floors—vibration, temperature swings, demanding cycle times, and round-the-clock operation. When your equipment investment pays for itself in months, you need reliability that lasts for years.

Complete Material Handling Solutions

Feeding doesn’t exist in isolation. Our systems integrate seamlessly with your existing material handling equipment, whether you’re running standalone machines or central conveying systems. We understand material flow from source to process because we design complete resin handling solutions. [LINK: Ultimate Guide to Blending]

Comprehensive Support

When you choose Novatec feeding systems, you’re not just buying equipment—you’re gaining a partner who understands your operation. Our technical support team includes specialists who’ve worked in plastics processing facilities and understand the real-world challenges you face. We’re available when you need us, whether during installation, optimization, or years down the road when you’re expanding capacity.

The Right Solution For Your Operation

No two processing operations are identical, which is why we offer feeding solutions spanning the full spectrum of applications:

Single-Component Dosers

Compact gravimetric feeders for machine-throat mounting deliver precise colorant or additive metering for processors who need accuracy without the complexity of multi-component systems. Perfect for simple color dosing or single-additive applications.

Liquid Color Pumps

Precision liquid color dosing systems integrate with gravimetric controls to provide accurate metering of liquid colorants with excellent dispersion properties. Ideal for applications requiring very low additive percentages with superior color uniformity.

High-Throughput Feeders

Larger-capacity systems for extrusion operations and high-volume injection molding, with dosing rates suited to demanding production requirements while maintaining precision control.

Multiple-Feeder Configurations

Installations supporting multiple feeders on single throat adaptors for equipment redundancy, rapid material changeovers, or simultaneous dosing of multiple additives.

Proven Results

Processors who’ve made the switch to gravimetric feeding consistently report:

- 20-40% reduction in colorant and additive consumption by eliminating over-dosing

- Payback periods of 6-18 months depending on throughput and material costs

- Near-zero rejects from color inconsistencies or property variations

- Dramatic reduction in material inventory and associated carrying costs

- Complete material consumption documentation for cost accounting and quality systems

- Elimination of time-consuming calibration procedures

Ready To Take Control Of Your Material Costs?

Most processors already know their feeding setup is costing them money. The colorant waste, the rejected parts, the time spent calibrating—it all adds up. What they don’t know is how quickly the right feeding equipment pays for itself. For many operations, material savings alone deliver ROI in under a year.

We talk to processors every day about feeding challenges—getting colorant consumption under control, eliminating color variation, reducing reject rates. The specifics differ, but the solution is almost always the same: stop guessing, start measuring.

Give us a holler or reach out on the form below to start a conversation about your feeding needs. Whether you’re running a single machine or a multi-line facility, processing commodity resins or specialty compounds, we’ll help you figure out the right solution for your operation.

No sales pitch. No pressure. Just a conversation about what’s possible when you have complete control over your material costs and product quality.

Because in plastics processing, control is everything.

Ask The Expert Blending

"*" indicates required fields