Central Plastics Drying and Plastics Conveying Controls

-

FlexXpand™ FX3 with NovaNet™ System Control

Manage Up to 160 Stations and 40 Pumps with Expandable Control System

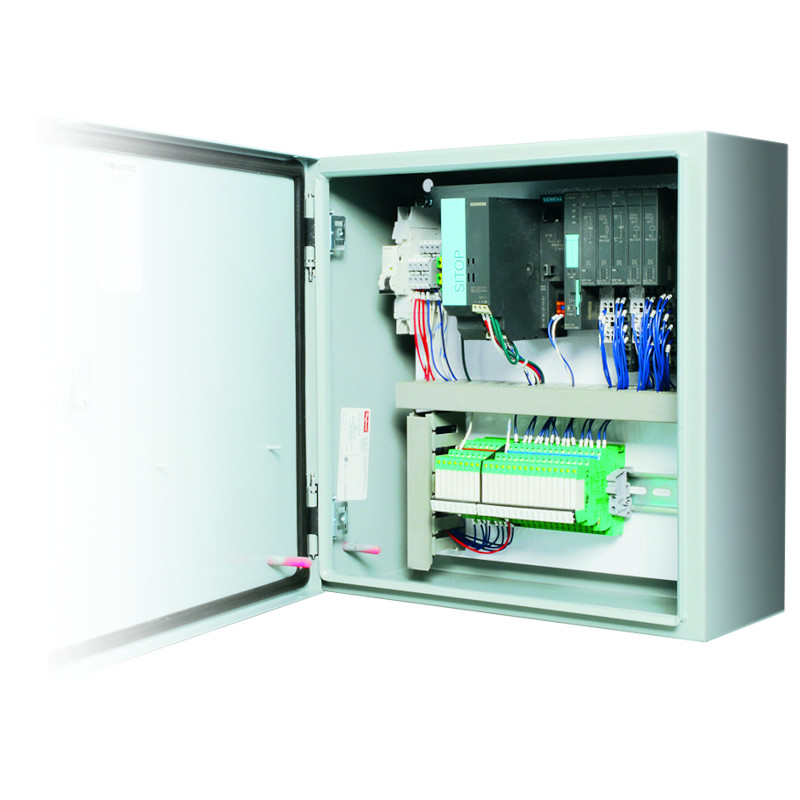

The FlexXpand FX3 system provides robust, expandable control for central conveying systems, with seamless integration of additional modules for enhanced functionality. Equipped with a Siemens PLC and intuitive color touch screens, the FX3 system sets the standard for flexible, scalable central control, allowing you to manage vacuum pumps, receivers, and more with precision and ease.

-

FX2 With NovaNet™ FlexXpand™ Expandable Central System Control

Control all Central Conveying Components PLUS Remote Access to Central Dryers, Silos, Silo ID Proofing, Railcar Unloaders, WSB Blenders and more…

FlexXpand with NovaNet and Color Touch Screen PLC – for Complete Central System Control with lower cost than older technologies.

-

CL Silo Manager

CL Silo Manager for up to 12 silos

The CL silo manager utilizes a Siemens LOGO! PLC monitors the fill levels of between four and twelve aggregate-filled silos using BinMaster ultrasonic sensors which properly calculate angles of repose and drainage. These values are graphically shown on a 4” color HMI mounted on the control box for the plant operators’ use. High and low level alarm set points can be entered from the HMI on a global basis.

-

OptiFlex Central Drying Hopper System Control

Control up to 3 Central Dryers and up to 48 Central Drying Assembly Hoppers

The OptiFlex (OFX) Central Drying Hopper Control utilizes a 10.4” color touch screen which communicates with all components of the central drying system (heaters, sensors, switches, etc.). The OptiFlex is configurable and expandable for use with up to 3 central dryers and up to 48 drying hoppers with the addition of OFMX I/O panels.

-

COMM Communication Modules

ProfiBus, Modem/ModBus, & Ethernet

Communications Modules add valuable features to NovaTouch™ Dryer and Conveying Controls