Receiver and Vacuum Pump Controls

-

FX2 Conveying System Control

For up to 160 stations and up to 20 vacuum pumps plus 1 backup

The powerful FlexXpand FX2 control system provides color touch screen PLC control with a wide range of built-in capabilities which can can be easily expanded with the addition of FlexXpand FXM2 modules. Available with 7″ or 12″ high resolution color touch screen interface.

-

FTS FlexTouch™ Recycled Material Conveying Control

FTS for up to 20 Grinder Evacuation Stations, 6 Collection Stations and 3 Vacuum Pumps

The FlexTouch FTS Control Series provides full featured control in an economical fixed I/O package for evacuating regrind and conveying it to collection stations. All grinder evacuation stations, recycle collection stations, pumps and optional material line valves connect to a single enclosure via discrete wiring.

-

MCS-400 Series Logo Control

Control from 1 to 6 Receivers and a Vacuum Pump

Compact, Mini-PLC Series for control of small central conveying systems.

-

FlexTouch™ Central Conveying Control

User friendly color touch screen PLC for up to 34 Receivers and 3 Pumps

The FlexTouch FTS control series provides full featured control in an economical ‘fixed I/O’ package.

-

MCS-600 Series Central Conveying Control

Use for up to 96 Receivers on DeviceNet Control Networks – Allen Bradley Platform

The MCS-600 Series Central Conveying Control offers fast, secure, plug-and-play installation using pre-terminated cable sets to interconnect I/O blocks assigned to each component in the central conveying system. Control up to 96 receivers, 16 vacuum pumps, 64 shared purge valves and material selection stations.

-

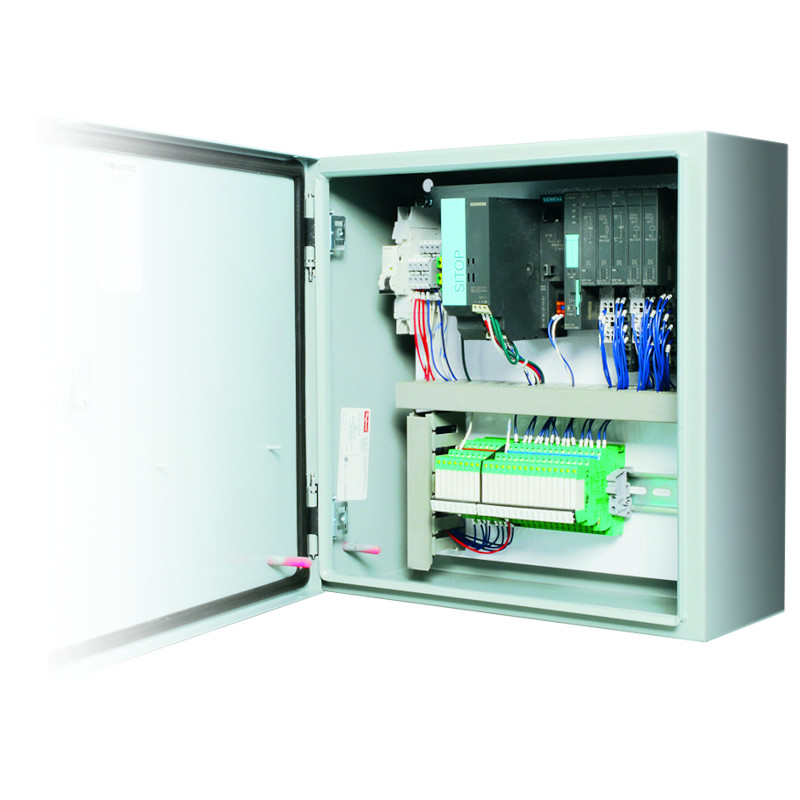

MCS(C) Allen Bradley Central Conveying Controls with Fixed I/O

Controls up to 34 Vacuum Receivers and 3 Vacuum Pumps plus up to 10 Purge Valves

The MCS(C) Fixed I/O controllers are Allen Bradley PLC based touch screen central loading controls, featuring intuitive operation in a compact,package. All receivers, pumps and purge valves connect to a single enclosure via discrete wiring.