System Valves and Accessories

The Importance of Valves and Accessories for Plastics Conveying Systems

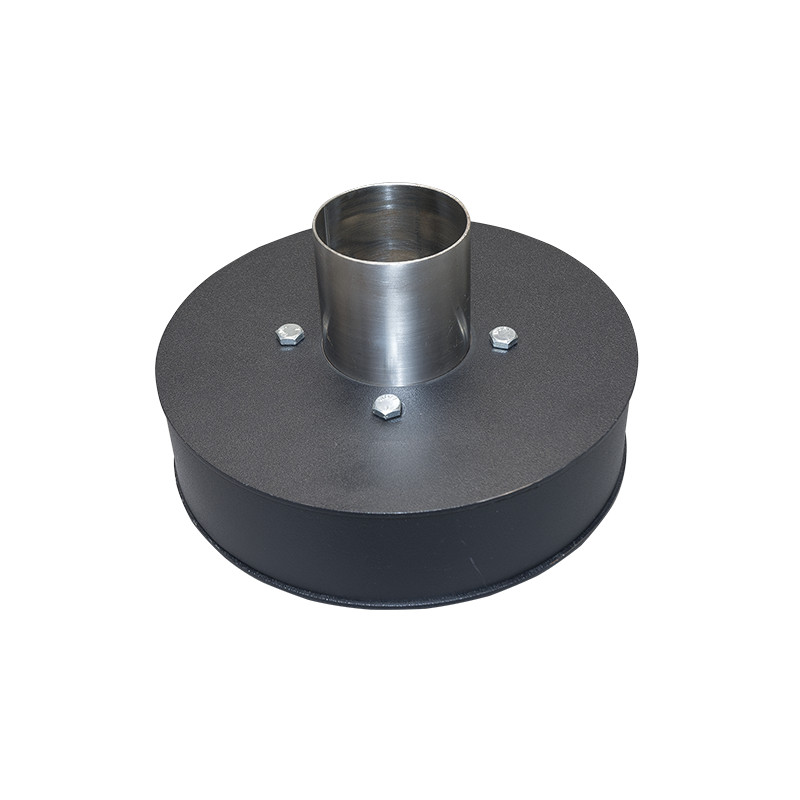

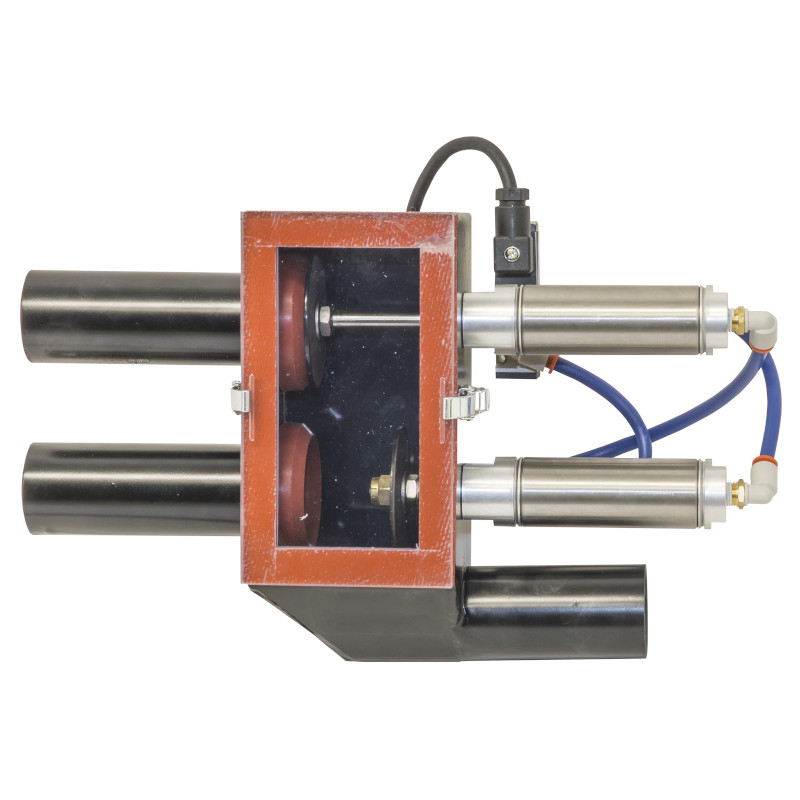

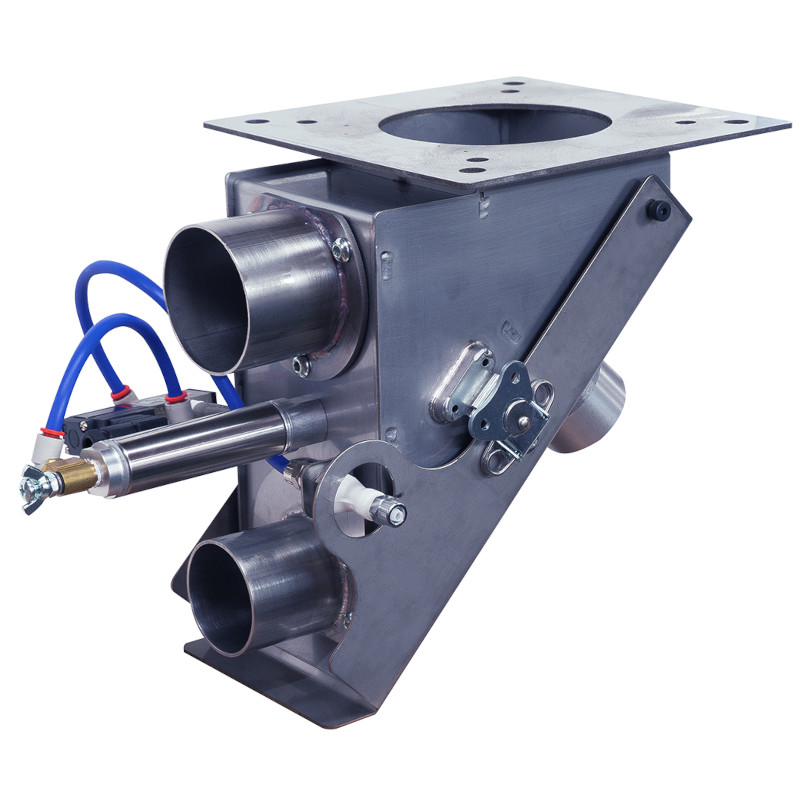

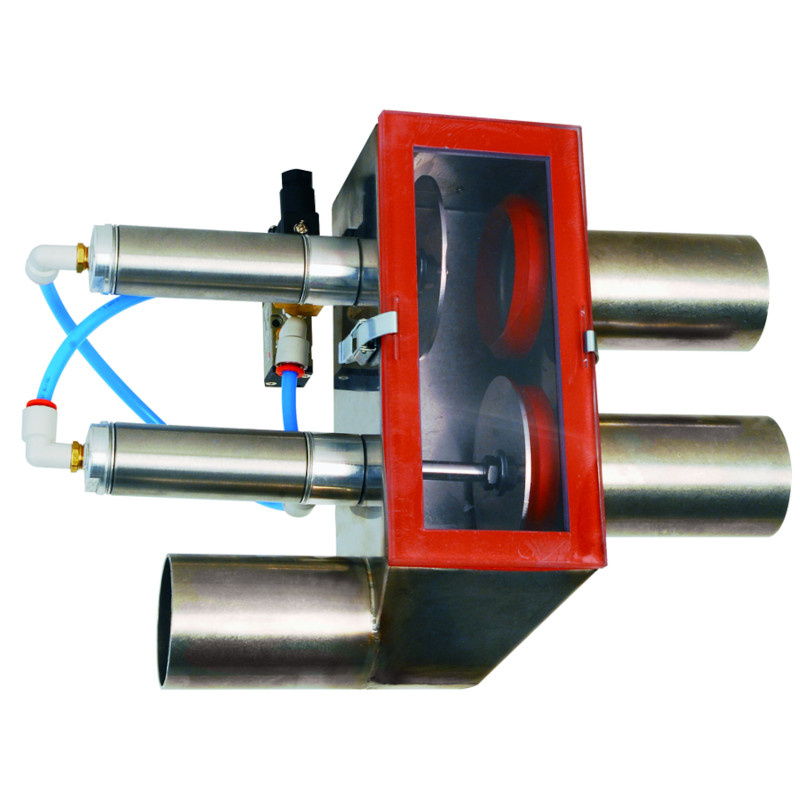

No selection of Plastics Auxiliary Equipment for Plastics Conveying Systems is complete without a wide array of valves and accessories to complement the Plastics Auxiliary Machinery.The list might include things like Machine Hoppers or Machine Bins which mount on machine throats. Other things that are likely included are Vacuum Purge valves, Proportioning Valves, External Line Valves, Discharge Selection Valves, Vacuum Takeoff Boxes, Closed Loop Relief Valves, Station T Sequencing Valves and External Line Valves.

These Plastics Conveying System Accessories all serve valuable purposes within systems used for conveying plastics pneumatically.