The Ultimate Guide to Compressed Air Resin Dryers for Plastics Processors

Introduction: Why Resin Drying Matters… and Why It’s Changing

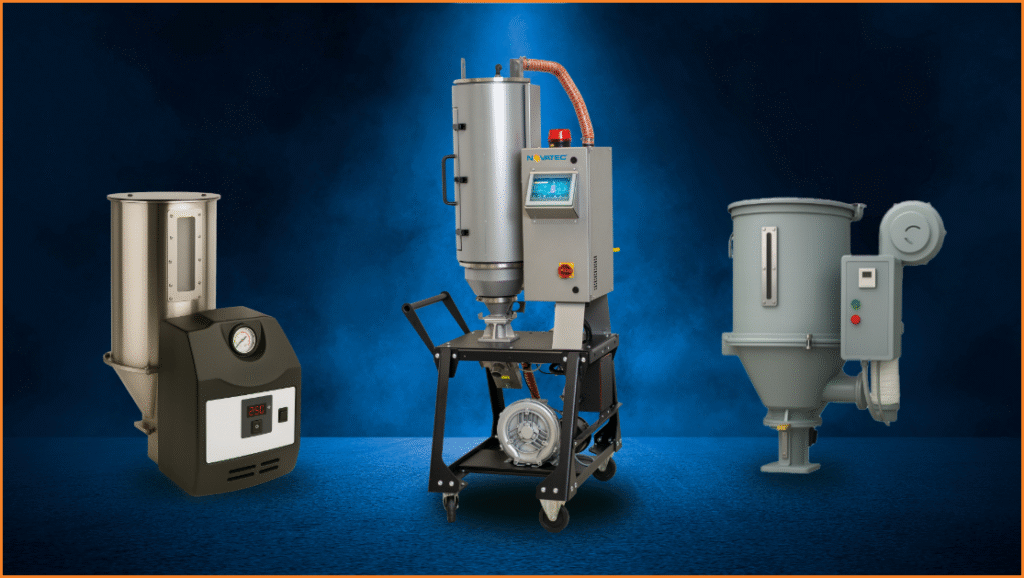

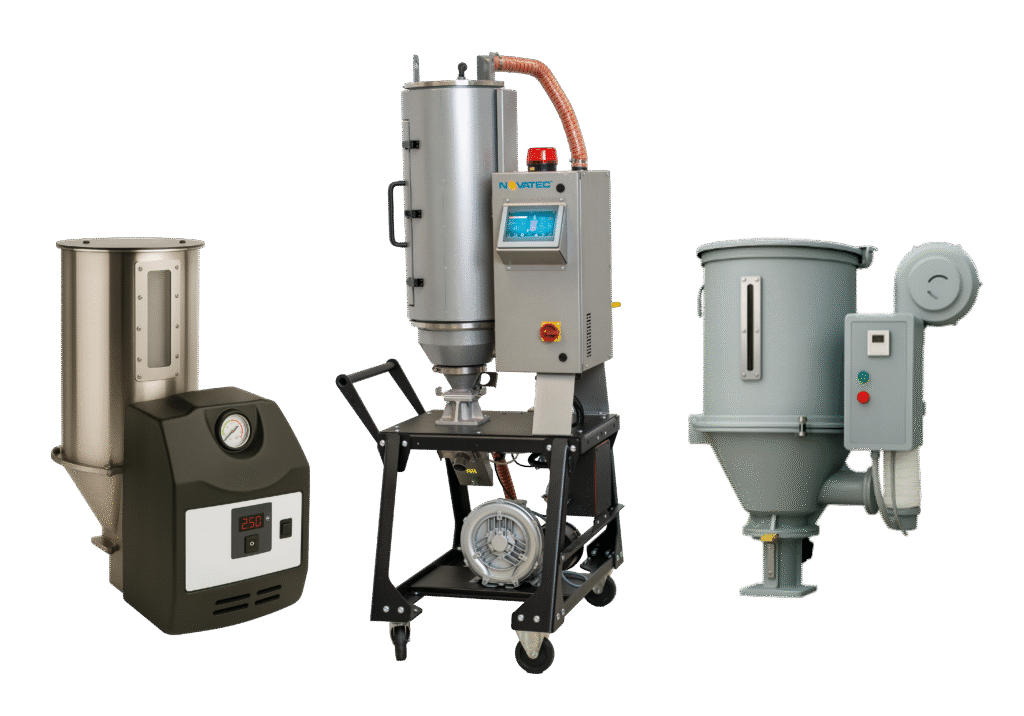

For decades, plastics processors have relied on various drying technologies to remove moisture from hygroscopic resins. From hot air dryers to desiccant bead systems to wheel dryers, each technology has carved out its place in the industry with distinct trade-offs between performance, throughput, and maintenance. Among these options, compressed air resin dryers have long stood out for one compelling reason: simplicity. No moving parts, no desiccant to regenerate, just clean dry air. But as we’ll explore in this guide, not all compressed air dryers deliver on that promise equally.

In plastics processing, moisture is the silent saboteur. It sneaks into hygroscopic resins like nylon, ABS, and polycarbonate, and if it isn’t removed, it shows up later as splay, bubbles, brittleness, or worse… weakened parts that can’t perform. Moisture doesn’t just affect appearances; it can break down polymer chains at the molecular level, leading to costly rejects and lost production time.

But over the past few decades, certain advanced compressed air dryers—with high-performance membranes and dual-flow designs—have steadily changed what’s possible. They’re now able to deliver the performance and higher throughputs that once required complex desiccant bead or wheel systems, while maintaining the simplicity and near-zero maintenance that made compressed air dryers attractive in the first place.

Before we dive into the different types, let’s start with the basics: what compressed air dryers actually are, how they work, and why not all are created equal.

Types of Compressed Air Dryers… and How They Work

At their core, compressed air dryers all work toward the same goal: taking the air you’re already generating in your plant and transforming it into ultra-dry heated process air that can strip moisture out of resin pellets. But how they go about it makes all the difference in performance, energy use, and maintenance.

Think of it like drying clothes on your back porch. You hang them outside on two different days, both 85°F. On a humid summer day when the air is already saturated with moisture, your clothes stay damp far longer…the wet air simply can’t absorb more water. On a crisp, dry autumn day at that same 85°F temperature, those same clothes dry quickly because the low-humidity air has plenty of capacity to pull moisture away. Resin pellets behave the same way. They hold onto internal moisture stubbornly, so the drier the air flowing over them—the lower the dew point—the better your results.

It’s worth emphasizing: airflow is the absolute critical factor in drying performance. Heat provides the energy to drive moisture out of the pellet. Dew point determines how much moisture the air can absorb. But airflow is what actually penetrates the resin bed, distributes that heat to every pellet, and carries the moisture away. Without sufficient airflow and pressure, even perfectly heated, ultra-dry air won’t reach the pellets that need it most. The upper portions of your hopper will remain cold and under-dried, no matter what your temperature gauge reads at the heater.

But it’s important to understand that ordinary compressed air dryers have carried two major problems that processors have been forced to work around. First, they delivered inconsistent drying performance because they were completely dependent on varying compressor performance conditions—vulnerable to dew point fluctuations that happened without warning. Second, once you pushed past about 10 pounds per hour, they consumed so much compressed air that plant compressors couldn’t keep up. The result: unpredictable part quality and limited throughput. That’s why many processors defaulted to desiccant wheel or bead dryers for larger jobs, despite the added moving parts, maintenance, and operating costs.

Over the years, compressed air dryers have taken three main forms:

Hot Air (Non-Desiccating) Compressed Air Dryers

These were the earliest attempts at compressed air drying. They simply heated expanded compressed air and pushed it through the hopper. But heating alone doesn’t solve the real problem—if the air isn’t truly dry, it can’t pull all the moisture from the resin, especially the troublesome internal moisture that causes the most problems downstream.

To understand why, it helps to know that drying resin effectively requires three critical components working together: heat, airflow, and dew point.

Heat is actually the easiest part to generate—you just need a heating element controlled to the resin manufacturer’s specified temperature—typically somewhere between 150°F and 350°F depending on the material. The heater monitors the temperature and modulates automatically to prevent overheating. Simple enough.

But here’s the critical distinction most people miss: the heater heats the incoming airflow, not the pellets directly. The heated air must then carry the heat throughout the hopper to uniformly reach every pellet. Without adequate and uniform airflow to distribute that heat evenly throughout the hopper, you’ll get cold spots, under-dried pockets, and inconsistent results. Heat without airflow is almost useless.

The challenge gets even tougher with engineering polymers: many must be dried at temperatures below 212°F—the boiling point of water. This matters more than most processors realize. Above 212°F, you can literally boil water out of resin, making moisture removal much easier. Below 212°F, moisture removal becomes moisture saturation limited, meaning you’re relying on thermal energy to drive moisture from inside the pellet to the surface, plus accelerated airflow to carry it away. It’s significantly harder and slower—and it absolutely requires uniform heat distribution to every pellet, which only happens with proper airflow.

Airflow is where things get tricky. Airflow is what delivers heat throughout the resin bed and carries away the evaporated moisture. But here’s what really matters: air velocity and pressure in the hopper itself—where the pellets actually are.

The airflow measurement at your compressor can look great on paper, but after passing through filters, pipe restrictions, and other system components, the actual velocity and pressure reaching your resin bed can be dramatically lower. And resin beds are always dense—making it difficult for air to push through and reach every pellet uniformly.

This matters more than most processors realize, especially for hygroscopic engineering resins. Remember, without sufficient air velocity, you can’t spread the temperature adequately throughout the hopper— some pellets never receive heated air in the first place, and even those that do may only get surface heating that never penetrates deep enough to drive out trapped internal moisture. Those water molecules deep inside stay put—comfortable, unmoved, and completely unaware they need to leave.

Dew point is the third component—the measure of how dry the incoming air itself is. Air with a lower dew point has far greater capacity to absorb moisture from the resin, especially trapped moisture in the pellet. On a humid day with high-dew-point air, your resin will likely never fully dry, no matter how much heat or airflow you apply plus typically you’re already starting at higher moistures as well. You’ll eventually dry it but not within the confines of the fixed amount of time you’ve set up. It’s like hanging clothes outside on a muggy summer day at 85°F versus a crisp autumn day at the same 85°F—the dry air makes all the difference.

But dew point without proper airflow and temperature can’t dry the pellets. Here’s what the industry doesn’t talk about enough: dew point alone doesn’t achieve complete drying. If the heat never reaches inside the pellet in the first place, or if there’s insufficient velocity to drive that heat deep enough and carry the moisture away, even perfectly dry -40°F air delivered to your hopper won’t save you. Dew point’s real job is to create the conditions that allow heat and velocity to do their final work—giving the air enough capacity to absorb and carry away moisture once the other two components have driven it to the pellet’s surface and started the diffusion process.

So why did dew point become the industry obsession? It happened alongside the rise of engineering resins in the 1970s and 80s—materials like nylon and ABS that had to be dried below 212°F, where you couldn’t just boil the water out anymore. Around the same time, relative humidity sensors became cheap and dead simple to use. Unlike airflow or velocity, which vary significantly from manufacturer to manufacturer, and were difficult to standardize or compare across different dryer designs, dew point is consistent—the same measurement regardless of whose equipment you’re using. It became the one metric everyone could agree on, test easily, and standardize across the industry. So -40°F became the universal benchmark—not because it tells the whole story, but because it was measurableand easy to verify.

The problem is, focusing only on dew point without proper attention to airflow and temperature led processors to overlook what really matters: getting heat deep into every pellet with enough velocity to pull that moisture out. That said, dew point consistency is important. You need consistent, low dew point air so the other two components can do their job reliably, every single time, especially when drying under 212°F is needed and also during the final finishing stage of removing trapped water within the pellet. That’s why advanced systems that deliver consistent -40°F regardless of compressor conditions matter. But dew point is still only one piece of the puzzle.

Hot air non-desiccating compressed air dryers solved the heat component, but they couldn’t deliver low enough dew points for hygroscopic engineering resins like nylon, polycarbonate, or ABS. That’s why they quickly became obsolete for serious plastics processing and are mostly a relic of the past today.

Desiccating Compressed Air Dryers

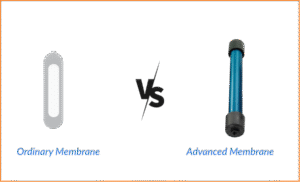

This is where compressed air drying made its real leap forward: by passing compressed air through a moisture-removing membrane before it ever touched the resin. With a high-quality membrane, you can achieve the ultra-low dew points needed for moisture to migrate out of resin pellets efficiently.

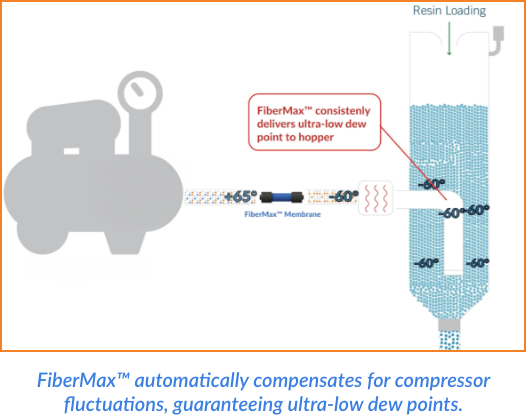

Your air compressor’s performance is never truly stable. Fresh off a service call, your compressor might deliver +50°F dew point air. A few months later, it could be delivering +65°F dew point air. Some compressors don’t even have a refrigeration circuit, so swings are even worse and now your compressor is suddenly delivering +85°F dew point air. All of these swings in dew point translate directly into inconsistent drying performance when you have an compressed air dryer with an ordinary membrane.

Here’s what happens: Yesterday, your compressor was in good condition, delivering relatively dry air to the membrane. That ordinary membrane filtered out enough moisture to bring your hopper’s process air down to a low dew point. That heated, dry air passed through the resin bed and pulled moisture out effectively. Your pellets came out at 200 PPM, perfectly to spec.

Today, running the exact same process settings, your parts are suddenly coming out at 600 PPM or 800 PPM…way above spec! What changed? Your compressor drifted. Maybe it’s been a few months since the last service. Maybe ambient humidity in your plant rose a bit. Maybe your compressor doesn’t have a refrigeration circuit, making it even more vulnerable to fluctuations. Whatever the reason feeding your membrane now carries more moisture in it.

And because ordinary membranes can only filter a limited amount of moisture, they can’t compensate for that higher incoming dew point. The process air going to your hopper ends up wetter too. The dew point in your hopper has risen without you knowing it. And now, unbeknownst to you, those pellets that looked perfectly dry on the surface are actually holding onto moisture inside.

You only discover it downstream when injection pressures start to shift, parts lose consistency, or rejects start piling up. By then, you’ve already made bad parts.

High-quality membranes, on the other hand, deliver consistently low dew points regardless of compressor condition or weather. They compensate for those fluctuations automatically, ensuring your hopper always gets the ultra-low dew point air it needs to effectively dry your resin to spec. They also waste far less compressed air during the membranes purging process.

Let’s talk about purge air for a moment, because it’s a critical part of how membranes work. When compressed air passes through a membrane, the membrane separates out the moisture. That moisture has to go somewhere—it can’t just stay in the membrane. So a portion of your compressor air, called purge air, carries that filtered moisture out of the membrane and vents it away. The more purge air a membrane needs, the less airflow is left available to actually dry the resin in your hopper. Ordinary membranes need roughly double the purge air compared to high-quality advanced membranes, which means they’re wasting compressed air before it ever reaches your resin.

Within desiccating compressed air dryers, there are two main designs used in plastics processing:

Single-Flow Systems

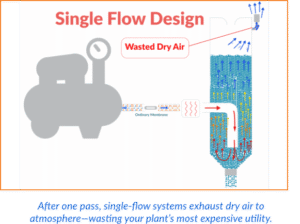

These were the first mainstream membrane dryers. With a high-quality membrane, single-flow systems can deliver consistent, ultra-low dew points and handle just about any resin type. But they have one big limitation: once the hot dry air passes through the hopper, it’s vented to the atmosphere. That means you’re constantly feeding in fresh compressed air… and compressed air is one of the most expensive utilities in your plant.

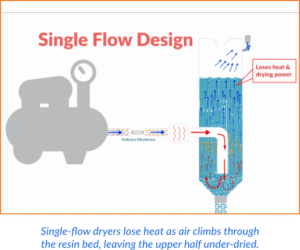

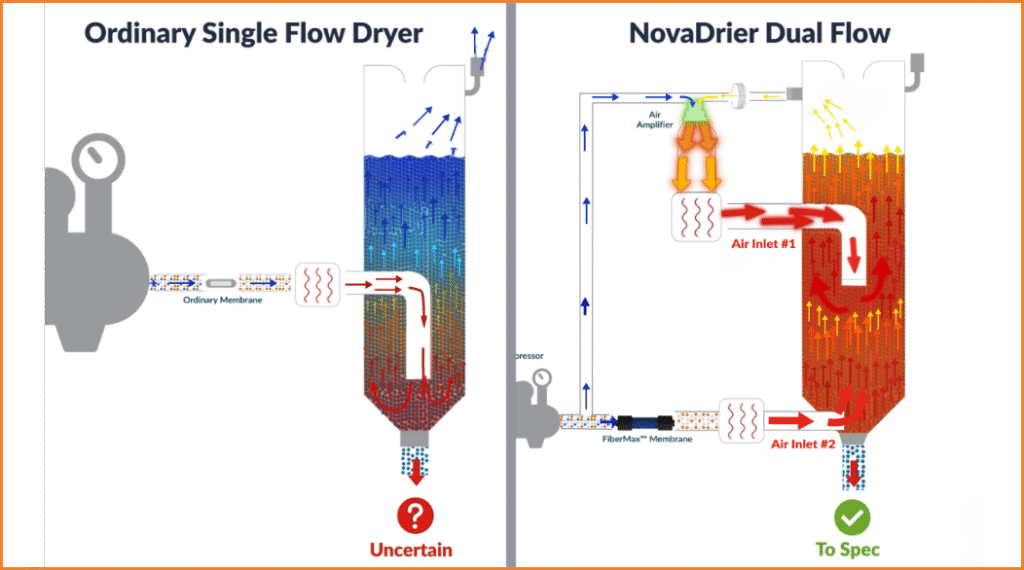

There’s another problem too. In a single-flow dryer, all the heated, dry air enters towards the bottom of the hopper. That works fine for very small hoppers processing 10 lbs/hr or less. But once you push past that, the resin bed becomes denser and taller. Now the air has to fight its way upward through that dense resin bed, and it loses heat and drying power as it climbs. By the time it reaches the upper portion of the hopper, it’s cooling off and has lost its punch. The entire upper half of the resin bed isn’t being penetrated with hot, dry air the way it should be.

Try to run them larger, and you risk maxing out your plant compressor, which is also feeding molding machines, robots, and tools. In other words, single-flow dryers hit a practical ceiling around 10 lbs/hr.

Dual-Flow Systems

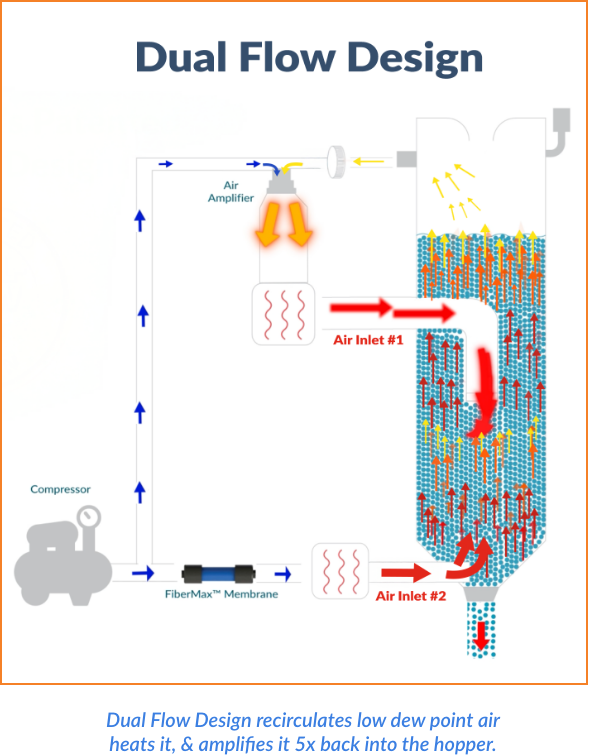

Instead of exhausting all the dry air after one pass, dual-flow systems recirculate most of it. That recaptured low-dewpoint air is then amplified by a venturi system, reheated, and reintroduced into the middle of the hopper, while fresh, heated ultra-low dewpoint air enters at the bottom. The result is better air and heat distribution across the entire resin bed, faster and more consistent drying, and far less compressed air consumption.

In fact, dual-flow systems cut compressed air usage by up to 65% compared to single-flow designs, allowing them to achieve the same throughput on a fraction of the compressed air that single-flow systems require. And with that efficiency, dual-flow dryers scale to throughputs of 75–100 lbs/hr—territory that once required far more complex desiccant wheel or bead dryers.

Desiccating Compressed Air Dryers vs. Traditional Desiccant Dryers

Traditional Desiccant Dryers (Beads or Wheels)

These systems use either twin towers packed with desiccant beads or a rotating desiccant wheel to strip moisture from the process air. They can handle high throughputs and achieve the ultra-low dew points processors need. The trade-off comes in the form of moving parts, regeneration cycles, and ongoing maintenance demands.

A typical desiccant wheel or bead dryer has blowers, motors, belts, valves, cooling coils, and the desiccant medium itself…all of which require upkeep. Beads eventually break down and need replacement. Wheels need to be regenerated and monitored. Each component introduces another maintenance interval, another source of downtime, and another potential expense on the balance sheet.

Desiccating Compressed Air Dryers (Membrane-Based)

By contrast, desiccating compressed air dryers use a moisture-removing membrane instead of beads or wheels. They have no moving parts, no regeneration cycles, and no desiccant medium to replace. The entire drying system comes down to a membrane and a couple of filters.

That unmatched simplicity — no moving parts, no belts, no blowers, no motors, just annual filter changes — is why processors have always loved compressed air dryers. No other drying technology comes close in terms of near-zero maintenance.

But for years, that simplicity came with a serious limitation: throughput.

The Old Trade-Off

Single-flow compressed air dryers with ordinary membranes, the dominant design for decades, suffered from two problems. First, they couldn’t compensate for fluctuating compressor dew points, so processors experienced unpredictable moisture levels in the resin without knowing why. Second, they were notoriously compressed air hogs. They dried the air, ran it through the hopper once, and then exhausted it into the atmosphere.

At small throughputs—under 10 lbs/hr—that was manageable. But push higher than that, and the dryer started consuming compressed air faster than many plants could supply it. Remember, that same air supply is also feeding injection molding machines, robotics, and auxiliary equipment.

This put processors in a corner:

• Use compressed air dryers and enjoy near-zero maintenance—but stay small or risk maxing out your compressor and live with inconsistent drying to boot.

• Or switch to desiccant bead or wheel dryers for higher throughputs—and accept the complexity, maintenance intervals, and downtime risk that comes with them.

It was a classic either-or decision… until dual-flow technology combined with advanced membrane systems changed the math entirely.

The Gamechanger: Dual-Flow, FiberMax™ Technology, and the NovaDrier

At Novatec, we know compressed air is one of the most expensive, tightly managed utilities in any plastics plant. And we also know the hard truth no one talks about: your air compressor’s performance is never truly stable.

That instability creates the invisible uncertainty that keeps processors up at night—wondering if today’s batch will dry the same as yesterday’s. And when you combine that with the throughput limitations of early compressed air dryers, processors were stuck choosing between simplicity and scale.

That’s why we spent decades perfecting a way to eliminate both problems: the inconsistency caused by ordinary membranes due to variable compressor dew points, and the throughput limits of single-flow designs.

The result is the NovaDrier—the industry’s first and only patented Dual-Flow Compressed Air Dryer, powered by our advanced FiberMax™ Membrane technology. We’ve been refining and proving this system for nearly 30 years. It’s bulletproof, it works, and thousands have been sold worldwide.

Here’s what makes it different:

FiberMax™ Advanced Membrane: Eliminating the Inconsistency

This is what sets advanced, high-quality membranes apart from ordinary ones. Ordinary membranes simply can’t do this. They fluctuate with your compressor’s performance. When your compressor drifts and starts delivering wetter air, ordinary membranes can’t compensate. The dew point in your hopper rises, your process suffers, and you often don’t even know it until bad parts pile up.

And because the FiberMax™ membrane is so efficient, it uses about half the purge air of ordinary membranes, leaving more airflow available to actually dry your resin. FiberMax™ membranes deliver up to two times the airflow efficiency compared to ordinary membranes, meaning more hot, dry air reaching your resin where it counts.

NovaDrier’s FiberMax™ membrane is also guaranteed for life. Unlike desiccant beads or wheels, it’s not a consumable. It’s a permanent solution to the inconsistency problem.

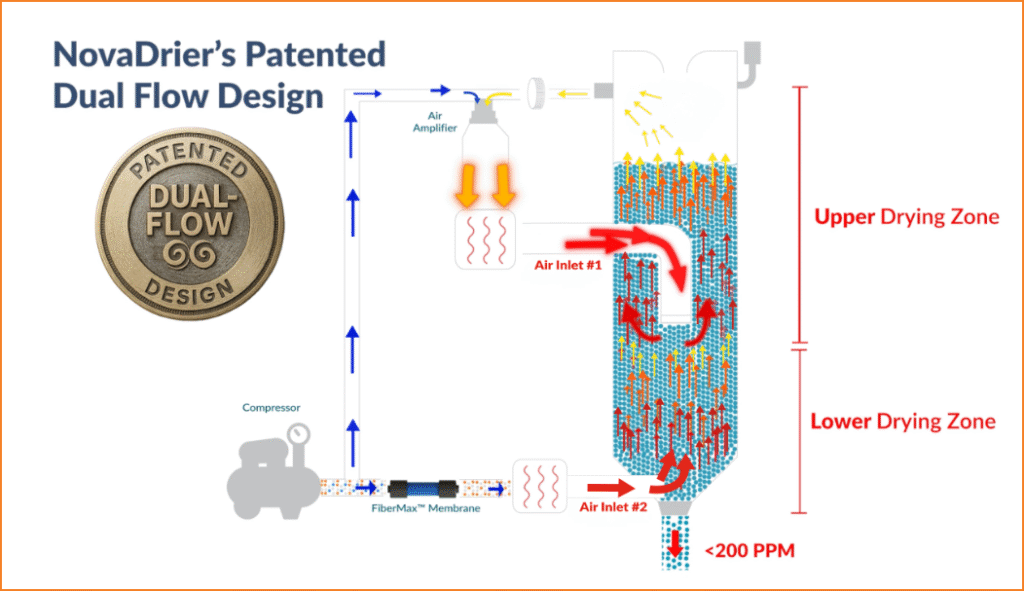

Dual-Flow Design: The Real Breakthrough

Picture a single-flow dryer in action. All the heated, dry air enters at the bottom of the hopper. It does most of its work down there, but as it climbs through the dense resin bed, it cools off and loses its drying power. By the time it reaches the upper half of the hopper, it’s lost its punch. The top of your resin bed is starving for hot, dry air while the bottom gets plenty. Single-flow dryers try to compensate by forcing more compressed air through, but that just drains your plant’s supply. And after all that work, the dry air exhausts out the top after one pass. Gone. Wasted.

NovaDrier changes that completely.

NovaDrier recaptures air from the top, amplifies it 5X, and delivers it to the

middle—creating two powerful drying zones for uniform moisture removal.

Heated, ultra-low-dew-point air from the FiberMax™ membrane enters at the bottom of the hopper, just like a single-flow system. But here’s where it gets different: after that first pass, NovaDrier captures that valuable, low-dew-point air from the top of the hopper instead of wasting it. That captured air is filtered, mixed with a small amount of air from your compressor, amplified five times using a venturi air amplifier, reheated, and then delivered back into the middle of the hopper—creating a powerful upper drying zone.

Now you have two super-powerful, heated low-dew-point air inputs working simultaneously: one in the middle of the hopper and one at the bottom. This creates true two-stage drying. The upper loop becomes the primary drying stage, removing approximately 75–80% of the moisture before the resin ever reaches the lower loop. The lower loop then acts as the finishing stage, ensuring every pellet exits at perfect spec.

Single-flow dryers leave the upper resin bed starving for heated air. NovaDrier’s

Dual-Flow delivers uniform heat throughout, ensuring every pellet exits to spec.

The result? Faster drying, uniform moisture removal from top to bottom, and dramatically more efficient use of compressed air. No hidden pockets of resin starving for heated dry air. Every pellet gets the airflow it needs.

And because NovaDrier reuses and amplifies air five times instead of wasting it, compressed air consumption drops by up to 65% versus single-flow designs. For example, a 50 lb/hr NovaDrier delivers that performance on just 10 CFM of compressed air—the same air demand single-flow systems need just to dry 10 lbs/hr. That efficiency is what lets NovaDrier models scale to 100 lbs/hr while keeping the rest of your plant’s air supply fully available for molding machines, robots, and tools.

And you still get everything processors have always loved about compressed air drying:

- No blowers

- No wheels or beads to regenerate

- No belts, motors, or valves to maintain

- Just two filters you swap out once a year

One of our customers proved the point better than we ever could. They outfitted their plant with 75 NovaDriers and reduced their entire maintenance team to one person whose only job was changing filters once a year. No downtime. No repair calls. No desiccant changes. Just reliable drying, day after day.

The Power of FiberMax™ + Dual-Flow: Zero Uncertainty

That’s the game-changer: NovaDrier’s FiberMax™ membrane eliminates the inconsistency caused by fluctuating compressor dew points, and the patented Dual-Flow design eliminates the throughput ceiling and airflow distribution problems of single-flow systems.

Together, they eliminate the uncertainty.

You never have to worry about fluctuating dew points or unpredictable drying performance. You never have to wonder if your compressor’s condition is affecting your parts. You never have to worry about hidden pockets of resin starving for heated air. Every pellet gets the airflow it needs, top to bottom, so your parts come out consistent, every single run.

That’s the power of Dual-Flow + FiberMax™ technology: unmatched consistency, efficiency, and simplicity scaled to the demands of modern production.

Final Thoughts: A Smarter Way to Dry

At Novatec, we believe drying shouldn’t be a daily battle. It should be in the background… quietly, reliably, and efficiently preparing your resin while you focus on production. That’s why we built the NovaDrier: to give processors the power of FiberMax™ + Dual-Flow drying and the ease of near-zero maintenance.

NovaDrier eliminates the inconsistency. It eliminates the uncertainty. It lets you sleep easy knowing your resin will always be dried to spec.

That’s NovaDrier. Perfectly dried resin. 65% less air. Near zero maintenance. Zero uncertainty.

Curious if it’s right for your plant? Give us a holler on the form below.

No sales pitch. No pressure. Just a conversation about what’s best for your operation.

Because the right dryer isn’t just another piece of equipment… it’s the key to smoother processing, lower costs, and a more productive plant.

Let’s figure it out together.

Ask the Expert: Drying

"*" indicates required fields

Ask the Expert