The Most Efficient Dust Collectors in Plastics Processing

Up to 99% dust removal without constant filter maintenance or performance degradation.

Up to 99% Dust Removal

Zero Moving

Parts

Parts

Maintains Peak Performance

Thousands

Sold

Sold

CDC Series Dust Collectors

For standard pellet conveying & general regrind applications

- Up to 99% dust removal before fines reach your machine filters — extends filter life from days to months with zero performance degradation over time

- Built for conveying application: Available for 3-25 HP pumps with 1.5-4″ inlet sizes, plus larger units up to 12″ for drying applications

- Heavy-duty construction: Free-standing heavy-gauge welded steel with sealed dust collection pan, backed by a 5-year warranty

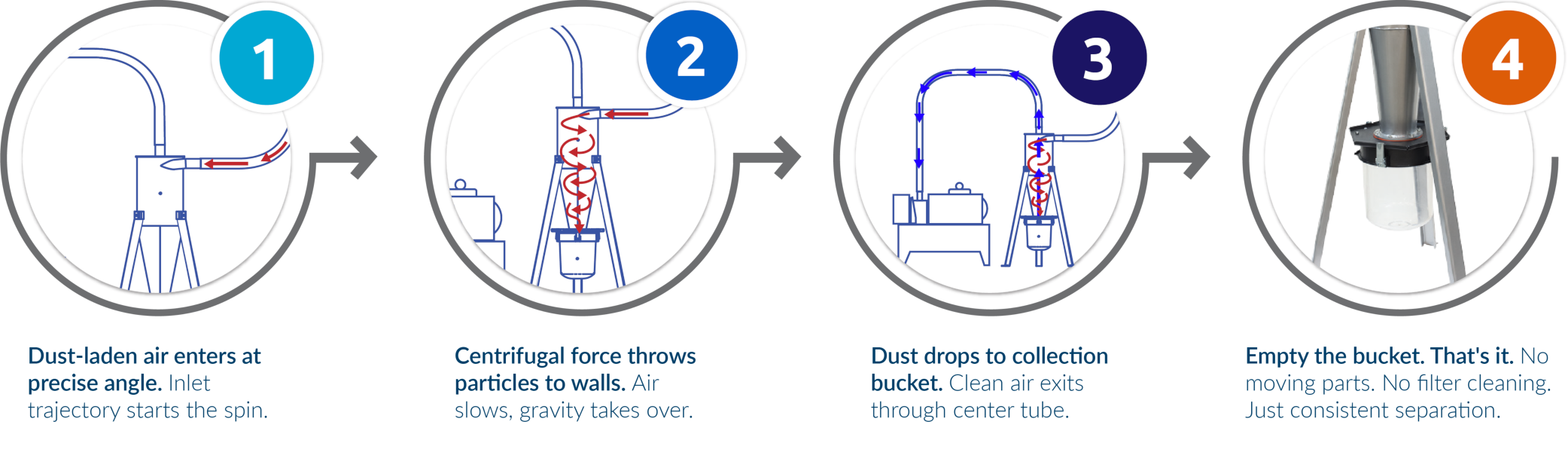

How it Works

Explore Novatec’s Vacuum Pumps

FDC Series Dust Collectors

For powders, pulverized materials, & excessively dusty regrind

- Dual-stage separation: Cyclonic pre-separation handles bulk dust load, then PTFE-coated cartridge filters capture particles down to 1 micron at 99% efficiency

- Automatic cleaning: Compressed air pulse-clean system maintains filter performance without manual intervention or production downtime

- Quick-change capability: Optional dual filter lid allows two-minute filter swaps instead of twelve — eliminating changeover downtime entirely

Up to 99% Efficient. Not 90%.

That 9% difference compounds every day you run material.

- Precision cyclone geometry captures up to 99% of fines — the 9% gap between us and generic cyclones ends up in your filters and pumps

- Thousands of installations proving it works: No moving parts, no performance degradation, just consistent dust removal year after year

Ready to Prevent Your Next Pump Failure?

Contact Us

"*" indicates required fields