Explore the Largest Selection of Advanced Resin Dryers

Perfected by Over 75 Years of Innovation & Expertise

Explore Our Resin Drying Technologies

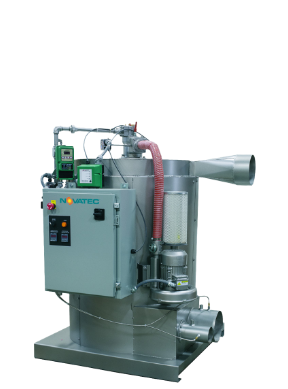

Engineered with the highest quality components and the most innovative features—backed by nearly a century of industry-leading insight, Novatec’s dryers deliver faster, more effective drying, so you can make more parts each day.

Centralized Drying Systems

Stop Wasting Labor & Floor Space…There’s a Better Way!

Novatec Knowledge Centers

Get expert insights and in-depth guides for resin drying.

Contact Us!

Whether you need a single portable dryer or a full-scale centralized drying system, our experts will ensure you get the perfect solution for your resin drying needs.