Drying Hoppers for Plastic Resins

Drying hoppers are part of most drying systems. They are usually sized to hold about four times the hourly throughput of the dryer they serve.

The operation of a resin drying hopper involves heating the air inside the hopper to a specified temperature and circulating it through the resin. The heated air absorbs moisture from the resin, drying it to the desired level. The hopper is typically equipped with a heater, a blower, and temperature and moisture sensors to monitor and control the drying process.

Resin drying hoppers are available in a range of sizes and capacities to meet the needs of different applications. They are typically made of stainless steel or other durable materials to withstand the harsh conditions found in industrial environments. Additionally, some resin drying hoppers are equipped with additional features, such as digital controls and alarms, to make the drying process more efficient and reliable.

Basic features you should look for in a resin drying hopper:

- Sizes range up to 18,000 lb. capacity

- Stainless Steel or Carbon Steel Construction – Depending on Size

- Insulation

- Elongated Sight Glass

- Large Access Door

- Slide-gate Shutoff and Drain

- Return Air Pellet Screen

- Mounting Bracket for Heater/Blower

Full insulation is the most important feature to ensure energy efficiency. The insulation should be at least 2” thick and should be included in the cone area as well as the sides of the hopper.

Types of Resin Drying Systems

Silo Dehumidification/ Hot Air Dryers

What is a silo dehumidifier and how does it work and compare with other resin drying systems?

The principle of compressing air in factories for power tools and other high-pressure uses has a side benefit for the world of resin drying.

What is a membrane resin dryer and how does it compare to a compressed air dryer without a membrane?

What is a vacuum resin dryer and how does it draw moisture away from plastic pellets in vacuum processing?

Dual Bed (also called Twin Tower) dryers used to be the most commonly purchased type of resin dryer. A look at why, and where the technology has progressed.

The advantages of desiccant wheel dryers include operating at a low temperature, which is important for preventing thermal degradation of the resin.

Technically, crystallizers are not dryers. They are used to convert PET from an amorphous, back to a crystalline state for re-processing.

Drying Hoppers for Plastic Resins

Drying hoppers are part of most drying systems. At a glance, they look much the same, but there are certain features you should look for.

What are the benefits of gas-fired process heaters for drying plastic resins?

Resin drying machines that can be moved from machine to machine within a plastics processing plant have advantages and disadvantages over a central drying system.

Properly designed Central Drying Assemblies are easily connected together to save installation costs.

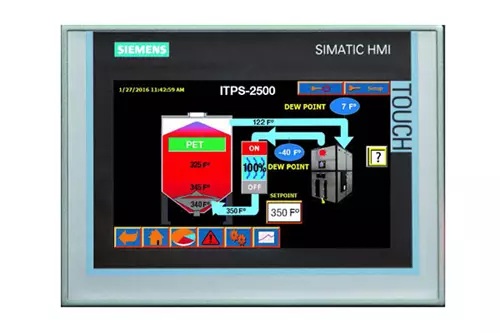

PET Energy-Saving Drying Systems

Learn about the keys to drying PET efficiently while saving space and energy.

Ask the Expert