Membrane Dryers

A membrane dryer is a type of compressed air dryer that uses a membrane to remove moisture and other contaminants from the air. The membrane is typically made of a polymer material, such as polyamide or polyurethane, and works by separating the water vapor and other contaminants from the compressed air.

The operation of a membrane dryer involves passing the compressed air through the membrane, which has a series of tiny pores. The pores allow the air to pass through while trapping the water vapor and other contaminants, which are then vented out of the system.

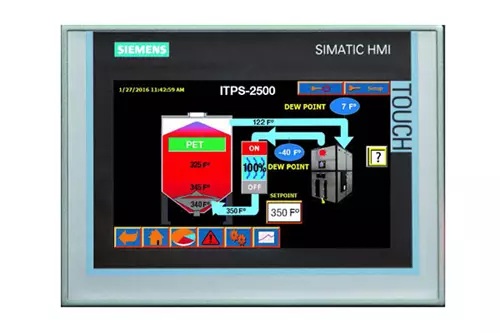

These dryers are commonly referred to as compressed air/membrane or membrane/compressed air dryers but the keyword is membrane. There is a big difference between a “compressed air dryer” and a compressed air dryer with a membrane. A compressed air dryer does not produce -40 dew point process air (it’s more like 0-20 dew point) and can vary week-to-week and season to season.

A membrane improves the compressed air dryer by ensuring -40 dew point process air so the drying capability of a membrane dryer is much better than a conventional compressed air dryer.

There is also a big difference between a membrane dryer with a built-in membrane as compared to one with an add-on membrane. Those with add-on membranes – use up to three times as much energy as as those with built-in membranes.

Types of Resin Drying Systems

Silo Dehumidification/ Hot Air Dryers

What is a silo dehumidifier and how does it work and compare with other resin drying systems?

The principle of compressing air in factories for power tools and other high-pressure uses has a side benefit for the world of resin drying.

What is a membrane resin dryer and how does it compare to a compressed air dryer without a membrane?

What is a vacuum resin dryer and how does it draw moisture away from plastic pellets in vacuum processing?

Dual Bed (also called Twin Tower) dryers used to be the most commonly purchased type of resin dryer. A look at why, and where the technology has progressed.

The advantages of desiccant wheel dryers include operating at a low temperature, which is important for preventing thermal degradation of the resin.

Technically, crystallizers are not dryers. They are used to convert PET from an amorphous, back to a crystalline state for re-processing.

Drying Hoppers for Plastic Resins

Drying hoppers are part of most drying systems. At a glance, they look much the same, but there are certain features you should look for.

What are the benefits of gas-fired process heaters for drying plastic resins?

Resin drying machines that can be moved from machine to machine within a plastics processing plant have advantages and disadvantages over a central drying system.

Properly designed Central Drying Assemblies are easily connected together to save installation costs.

PET Energy-Saving Drying Systems

Learn about the keys to drying PET efficiently while saving space and energy.

Ask the Expert