Portable Resin Drying Systems

The use of Portable Dry/Convey units has to be weighed against Central Drying/Conveying to see which option is best for any given processor.

The concept of a drying system that can move from machine to machine actually developed with the processors themselves who modified equipment into portable devices.

Portable drying machines enable processors to:

- Install other auxiliaries on their machines

- Eliminate tall, potentially unsafe drying hoppers on machine throats

- Pre-heat material elsewhere, prior to actual processing at the machine

- Rapidly remove drying equipment from the machine for cleanout and material change

- Do cleaning and maintenance in other, better suited, locations

- Use drying equipment to be only when necessary, and to remove it at other times

All of these reasons make a great deal of sense if you are only doing occasional drying.

Central drying/conveying is the most efficient way to get materials to your machines if:

- You have dryers on 10 or more machines

- You have a single material that requires drying and it is required at multiple machines

- You have frequent material changes on your machines

- You use more material types than you have machines

- You have dryer to dryer quality issues when drying the same material

- You want to expand, but do not have sufficient space

Types of dryers available in portable models include:

- Desiccant Wheel Dryers

- Dual Bed Desiccant Dryers

- Compressed Air/Membrane dryers

These models include the Dryer, Drying Hopper with a Vacuum Receiver a Vacuum Pump, all mounted on a frame with casters. A Machine-Mounted Vacuum Loader or Receiver is also supplied to be mounted on the process machine throat. It is not practical to use them for throughputs above about 200 lb./hr. because the unit would simply be too large to push around the plant floor.

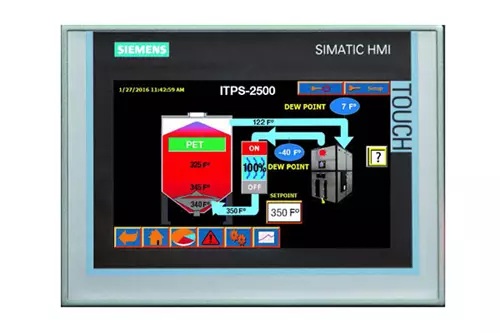

Controls have to be designed for both drying and conveying functions. Some microprocessor controls use various codes to describe errors and function buttons for programming parameters. There are also touch screen controls with intuitive icons and keypads for programming functions. With touch screen controls, errors are clearly spelled out in easily understood text messages. There are even controls that include features like over-drying protection for moisture-sensitive resins like nylons and photo-enhanced maintenance and trouble-shooting guides.

Some manufacturers charge extra for things like a warning light or a dew point analyzer, while others include those as standard.

Types of Resin Drying Systems

Silo Dehumidification/ Hot Air Dryers

What is a silo dehumidifier and how does it work and compare with other resin drying systems?

The principle of compressing air in factories for power tools and other high-pressure uses has a side benefit for the world of resin drying.

What is a membrane resin dryer and how does it compare to a compressed air dryer without a membrane?

What is a vacuum resin dryer and how does it draw moisture away from plastic pellets in vacuum processing?

Dual Bed (also called Twin Tower) dryers used to be the most commonly purchased type of resin dryer. A look at why, and where the technology has progressed.

The advantages of desiccant wheel dryers include operating at a low temperature, which is important for preventing thermal degradation of the resin.

Technically, crystallizers are not dryers. They are used to convert PET from an amorphous, back to a crystalline state for re-processing.

Drying Hoppers for Plastic Resins

Drying hoppers are part of most drying systems. At a glance, they look much the same, but there are certain features you should look for.

What are the benefits of gas-fired process heaters for drying plastic resins?

Resin drying machines that can be moved from machine to machine within a plastics processing plant have advantages and disadvantages over a central drying system.

Properly designed Central Drying Assemblies are easily connected together to save installation costs.

PET Energy-Saving Drying Systems

Learn about the keys to drying PET efficiently while saving space and energy.

Ask the Expert