Silo Dehumidification / Hot Air Dryers

[Airflow 150-250 cfm]

Metal silos are affected by the weather conditions surrounding them. They can become damp internally from sweat on their sidewalls caused by changes in humidity and temperature. This moisture can be transferred to the material stored in the silo.

Silo dehumidifiers are not intended to dry the material stored inside the silo. Instead, they operate on the simple principle of providing a blanket of dry air in the space above the material to keep the material from picking up additional moisture while in storage.

Silo dehumidifiers are usually installed in the base of a silo and one dehumidifier may serve more than one silo.

A resin silo dehumidifier is a device used to remove moisture from the air inside a resin silo. The dehumidifier works by using a desiccant material to absorb moisture from the air.

The dehumidifier consists of a housing unit that contains the desiccant material, which is typically a silica gel or molecular sieve. The housing unit also contains a fan that circulates the air inside the silo through the desiccant material.

As the air passes through the desiccant material, the moisture in the air is absorbed by the desiccant, leaving the air dry. The dry air is then released back into the silo, helping to maintain the desired humidity level.

5 Tips for Choosing a Resin Silo Dehumidification System

- Capacity: Choose a dehumidifier that is appropriate for the size of your resin silo. The dehumidifier should be able to handle the volume of air in the silo and maintain the desired humidity level.

- Efficiency: Look for a dehumidifier that is energy efficient, as this will help you save on energy costs in the long run. Check the dehumidifier’s energy consumption and compare it to similar models to find the most efficient option.

- Durability: Choose a dehumidifier that is built to last. Look for a model with a sturdy construction and quality components that can withstand the harsh conditions often found in industrial environments.

- Maintenance: Consider the ease of maintenance when choosing a dehumidifier. Look for a model that is easy to clean and has easily accessible components that can be replaced if necessary.

- Features: Consider any additional features that may be useful for your specific needs. For example, some dehumidifiers may come with a digital control panel, automatic shut-off, or the ability to adjust the humidity level. Choose a model with features that will make it easier for you to use and maintain the dehumidifier.

Types of Resin Drying Systems

Silo Dehumidification/ Hot Air Dryers

What is a silo dehumidifier and how does it work and compare with other resin drying systems?

The principle of compressing air in factories for power tools and other high-pressure uses has a side benefit for the world of resin drying.

What is a membrane resin dryer and how does it compare to a compressed air dryer without a membrane?

What is a vacuum resin dryer and how does it draw moisture away from plastic pellets in vacuum processing?

Dual Bed (also called Twin Tower) dryers used to be the most commonly purchased type of resin dryer. A look at why, and where the technology has progressed.

The advantages of desiccant wheel dryers include operating at a low temperature, which is important for preventing thermal degradation of the resin.

Technically, crystallizers are not dryers. They are used to convert PET from an amorphous, back to a crystalline state for re-processing.

Drying Hoppers for Plastic Resins

Drying hoppers are part of most drying systems. At a glance, they look much the same, but there are certain features you should look for.

What are the benefits of gas-fired process heaters for drying plastic resins?

Resin drying machines that can be moved from machine to machine within a plastics processing plant have advantages and disadvantages over a central drying system.

Properly designed Central Drying Assemblies are easily connected together to save installation costs.

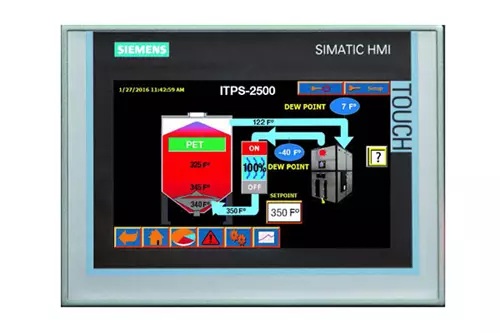

PET Energy-Saving Drying Systems

Learn about the keys to drying PET efficiently while saving space and energy.

Ask the Expert