Bulk Plastics Materials Handling

About Bulk Plastics Storage

Almost any Plastics Conveying System requires inclusion of Plastics Bulk Storage as well as Bulk Plastics Materials Loading and Unloading. This includes plastics Storage Silos, Railcar Unloading of plastics, indoor Bulk Bins (or Surge Bins) for plastics and even unloading of bulk boxes (often called Gaylords) of plastics materials. There are even bulk bag unloaders.

The particular requirements of a processors plastics conveying system will dictate the extent and type of bulk plastics storage and handling that is required.

-

Silo Storage

12′ Diameter Storage Capacities to 6,500 cu.ft. (larger diameters and capacities available)

Storage silos are an integral part of any large material conveying system. Always having material available and the ability to purchase material in bulk minimizes waste and opens up valuable floor space.

-

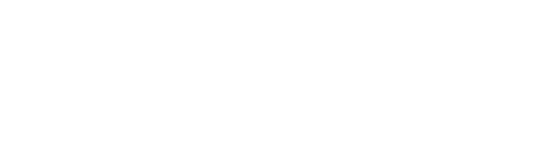

RCU Railcar Unloading System

25-75 Hp (18-56 kW)

Railcar unloading systems now available with RailSense which monitors and diagnoses potential maintenance issues before they become critical. Registration and continued use of RailSense extends the railcar unloader warranty frmn 3 years to 5 years.

-

MSB Series Modular Surge Bins

30-70 cubic ft (850-1980 liters)

MSB Series Surge Bins provide expandable material storage space and can be integrated into a central conveying system.

-

SB Series Surge Bin

100-458 Ft.3 (2832- 12969 liters)

SB Series Surge Bins are sized according to their usable volume and not “air” capacity. Each bin is constructed of rugged carbon steel, cleaned thoroughly on the inside and sandblasted/enamel painted on the outside. Standard features include hi/low sight glasses, hi/low couplings for level sensing, an inspection hatch and a 12” hole/bolt pattern for a Novatec loader or receiver.

-

SW Series Sweeper System

1.5″ – 2.5″ (40-75cm) Material Lines

The Sweeper™ automatically unloads material from bulk boxes without human intervention.

-

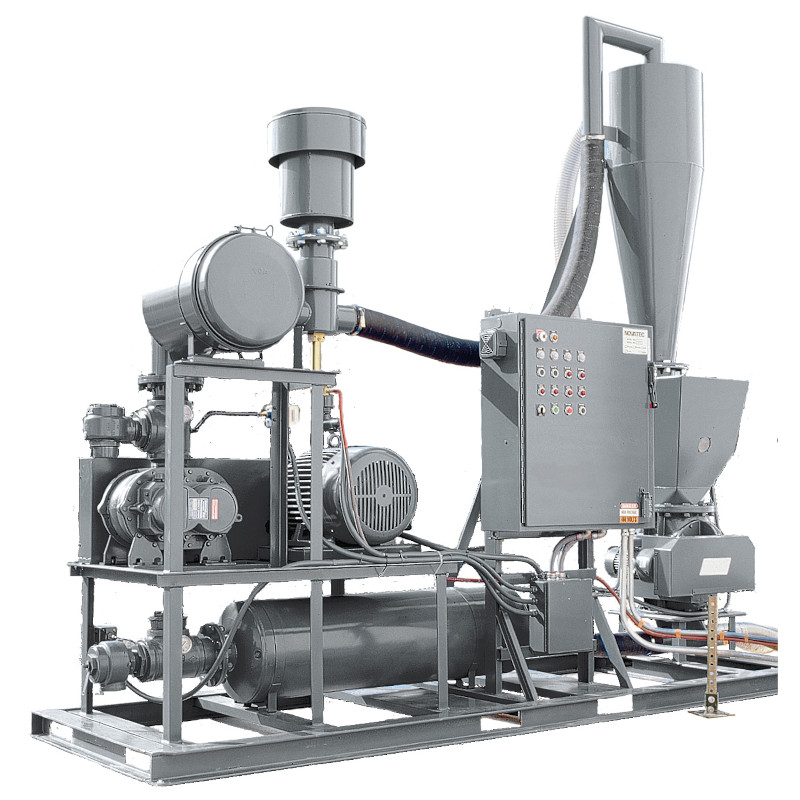

TT Series Tilt Table

2500: 2,500 lb. (1135 kg) Rating

Tilt table with floor level platform to automatically tilt gaylord to one corner allowing continuous evacuation of material.

-

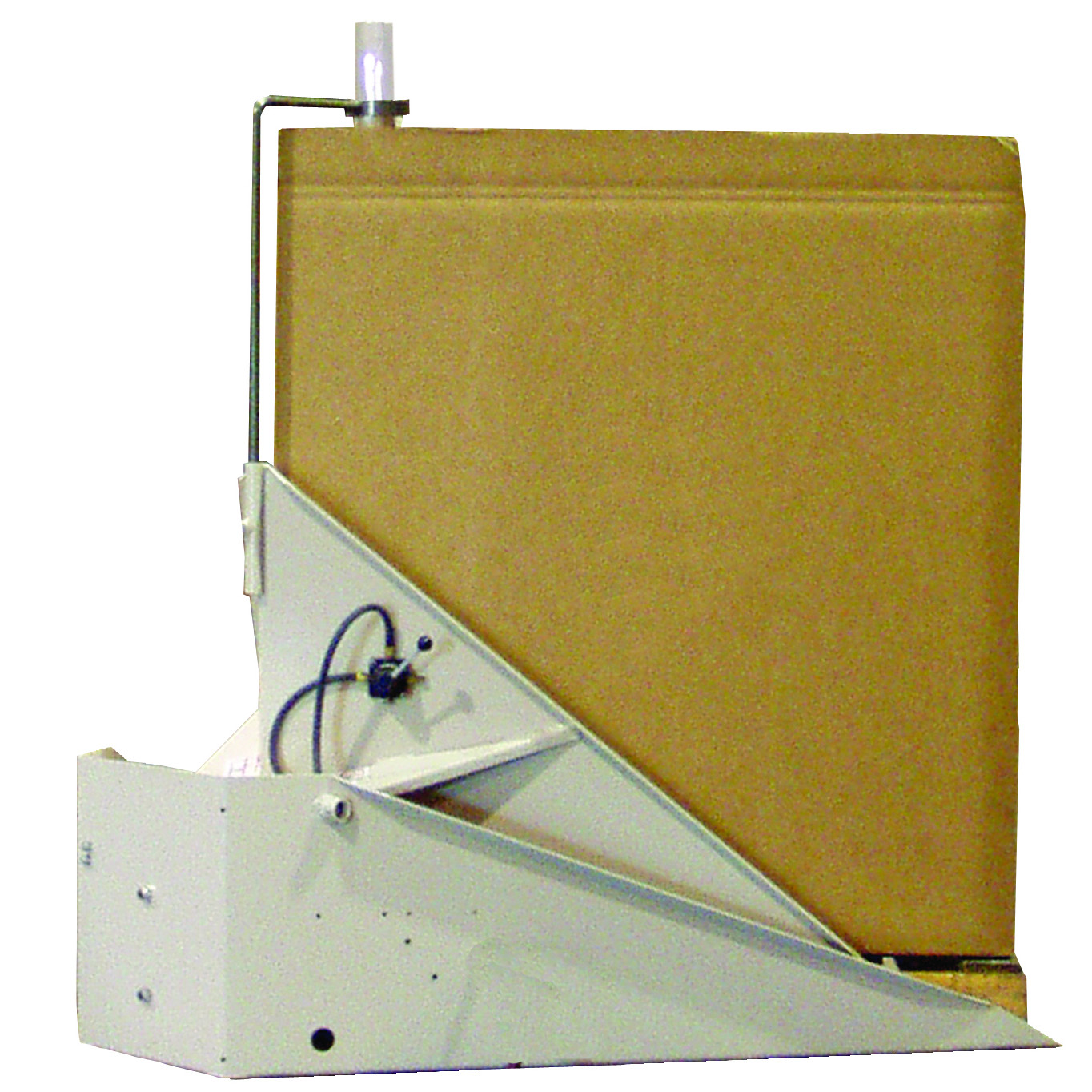

DM Series Drawer Magnet

Low Profile Design

The DM Series Drawer Magnets provide collection of ferrous metals with a rugged metal chamber which is typically match drilled and bolted directly to processing machine throat.

-

EMS Electronic Metal Separator

2″ & 3″ (50 & 75mm) Throats

Removes both ferrous and non-ferrous metals from material flow at the machine throat.