Reduce Your Dry Time By 50% So You Can Make More Parts Each Day!

Upgrade Your Dryer w/ The Only Automated Input Moisture Analysis Technology

- Automatically Adjusts Your Dryer’s Parameters

- Make Perfectly Dried Parts In The Least Amount Of Time

Watch How DryerGenie Works

Part Production

Energy Bills

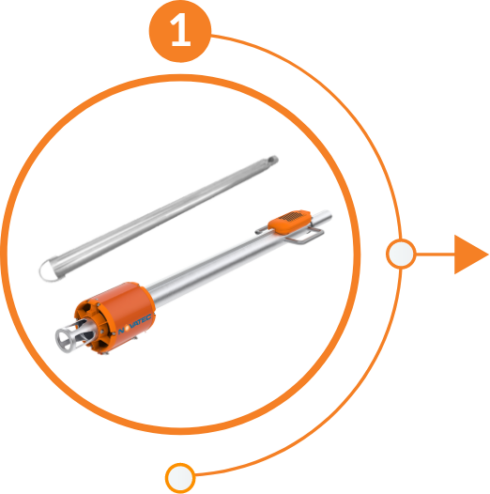

3 Easy Steps To Perfectly Dried Parts

Say Goodbye to Inaccurate

& Wasteful Time-Based Drying

Time-based drying was developed a half-century ago because nobody could answer the big question: what’s the starting moisture?

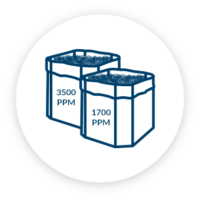

These same resins have a completely different moisture content from gaylord to gaylord, so why dry them the same?

Traditional Plastic Moisture Analyzers are far too expensive…and they only measure the plastic moisture content after the production run begins!

Say Hello To The Vast Savings

Of Condition-Based Drying

- The only way to adjust dry time automatically is at the front of the process!

- Dryer Genie knows the resin moisture content BEFORE the dry cycle begins.

- Automatically adjusts your dryer’s parameters guaranteeing the most perfect dry in the shortest amount of time.

- Produce so many more parts per run while decreasing your energy usage!

Features

Affordable

Costs tens of thousands less than traditional plastic moisture analyzers. Make your investment back in less than 3 weeks!

Automated

Never worry about over-drying or under-drying and let the Genie do all the work!

AI-Driven Accuracy

Advanced sensors & specialized algorithms calculate exact moisture content of your resins.

DryerGenie Annual Savings For (1) Dryer

Based on Drying PC/ABS in NWB-200 Dryer

DryerGenie Pricing

DryerGenie Pays Itself Off In Less Than 3 Weeks!

Hardware

$2,500

One Time Purchase

Software Subscription

$24.99/Month

Based on Annual Agreement

FAQ's

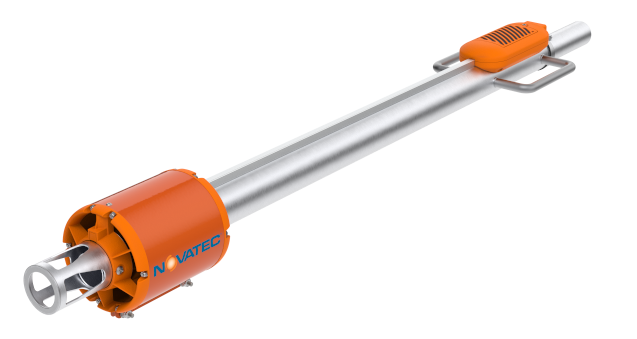

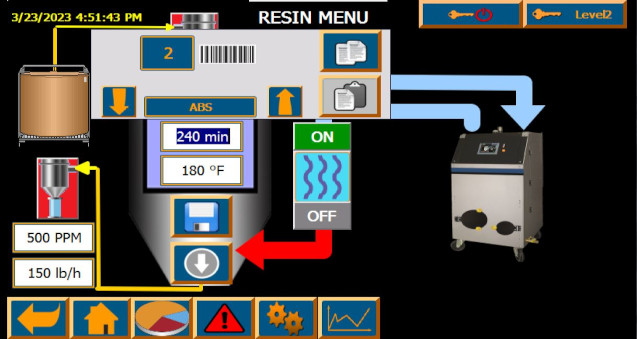

DryerGenie is a new way to guarantee your resin pellets are dried perfectly in the least amount of time. It consists of a replacement pick-up lance which houses an advanced moisture measurement sensor array system along with upgraded software for your dryer’s onboard processor that utilizes specialized algorithms to analyze the moisture data in real-time before the drying process begins and then automatically optimizes your dryer’s parameters for the most perfectly dried parts in the shortest amount of time.

DryerGenie solves the missing variable in your resin drying process by analyzing the moisture content of your pellets in a PPM basis at the start of the drying process so you can save energy, make parts that are never under-dried or over-dried, and increase your daily part production by not having to follow the antiquated constraints of the manufacturer’s estimated dry time.

No, DryerGenie is available on all 2016 and up Novatec dryers.

Please contact your rep to see if DryerGenie is available for your dryers.

Installation of DryerGenie is easy and simple. DryerGenie replaces your existing pick-up lance with an upgraded lance that possesses an advanced capacitance sensor array system.

Installation entails attaching the new DryerGenie lance to your dryer’s vacuum hose. DryerGenie also utilizes an upgraded software system that possesses specialized algorithms. Installation is fast and hassle-free.

DryerGenie consists of hardware, which is a one-time purchase of $2,500 as well as a cloud software system, which costs $18.99/month.

DryerGenie consists of a sensor array system that houses numerous sensors such as capacitive liquid sensors, humidity sensors, temperature sensors, pressure sensors, accelerometer sensors, and gyroscopic sensors which work in combination with an artificial intelligence processor with specialized algorithms to sense the moisture of your resin on the molecular level in real-time.

This real-time moisture data is then sent to the upgraded DryerGenie software system in your dryer’s onboard processor which automatically adjusts the dryer’s residence dry time, blower speed, and temperature for the most optimized drying process in the least amount of time.

,500

One Time Purchase

Software Subscription

.99/Month

Based on Annual Agreement

FAQ’s

DryerGenie is a new way to guarantee your resin pellets are dried perfectly in the least amount of time. It consists of a replacement pick-up lance which houses an advanced moisture measurement sensor array system along with upgraded software for your dryer’s onboard processor that utilizes specialized algorithms to analyze the moisture data in real-time before the drying process begins and then automatically optimizes your dryer’s parameters for the most perfectly dried parts in the shortest amount of time.

DryerGenie solves the missing variable in your resin drying process by analyzing the moisture content of your pellets in a PPM basis at the start of the drying process so you can save energy, make parts that are never under-dried or over-dried, and increase your daily part production by not having to follow the antiquated constraints of the manufacturer’s estimated dry time.

No, DryerGenie is available on all 2016 and up Novatec dryers.

Please contact your rep to see if DryerGenie is available for your dryers.

Installation of DryerGenie is easy and simple. DryerGenie replaces your existing pick-up lance with an upgraded lance that possesses an advanced capacitance sensor array system.

Installation entails attaching the new DryerGenie lance to your dryer’s vacuum hose. DryerGenie also utilizes an upgraded software system that possesses specialized algorithms. Installation is fast and hassle-free.

DryerGenie consists of hardware, which is a one-time purchase of $2,500 as well as a cloud software system, which costs $18.99/month.

DryerGenie consists of a sensor array system that houses numerous sensors such as capacitive liquid sensors, humidity sensors, temperature sensors, pressure sensors, accelerometer sensors, and gyroscopic sensors which work in combination with an artificial intelligence processor with specialized algorithms to sense the moisture of your resin on the molecular level in real-time.

This real-time moisture data is then sent to the upgraded DryerGenie software system in your dryer’s onboard processor which automatically adjusts the dryer’s residence dry time, blower speed, and temperature for the most optimized drying process in the least amount of time.