Introducing Novatec’s New DryerGenie

Novatec’s New DryerGenie Provides Starting Resin Moisture and Automatically Adjusts Drying Parameters for An Energy-Saving, More Efficient Drying Process

Novatec, Inc. will unveil their new DryerGenie product during the PTXPO 2023 trade show on March 28-30, Rosemont, Ill. The system combines moisture-measurement technology with drying technology to accurately measure the initial moisture content of the resin to be processed and communicates that information to the dryer controller. The dryer controller will automatically adjust drying time and temperature to coincide with the moisture reading before processing the material.

Novatec introduces ‘Smart Drying’ with their new DryerGenie .

The DryerGenie combines drying technology with startup and real-time moisture technology to eliminate the guesswork and wasted time and energy associated with time-based drying.

“To truly advance drying plastic resins, you need to look at how things have been done and understand the parts of the process that should be improved”, said Novatec’s CEO and co-owner Conrad Bessemer. He continued, “By doing just that, we found a way to change the drying paradigm with this new technology. We purchased a Swiss-owned company with expertise in moisture analysis. With our experience in drying, we teamed up to create a product that will precisely measure resin moisture and automatically adjust the drying time and other parameters to produce a consistently dry output. If you know what is going in, you can guarantee what is coming out.”

Bessemer explained, “The long-accepted standard in drying is to dry resin on a timed interval and an assumption of the wetness of material. But resins, even in sealed boxes and bags, can have wildly different internal moisture levels depending on ambient conditions, storage, packaging, and more.”

He continued, “By knowing and understanding the initial or starting moisture content of your resin and then properly drying resin to the resin manufacturer’s recommended dryness level, you will maintain the intended performance characteristics of the resin and yield a high-quality, cost-effective part.”

Mark Haynie, Novatec Vice President Moisture & Drying Technology, said, “Most drying times from resin data sheets include significant safety factors, which result in over-drying, wasted time, and wasted power. In most cases, the starting moisture point is unknown. Even two gaylords received on the same day can have dramatically different starting moisture points. To that point, we recently received two gaylords of nylon 66 from the same supplier on the same day. One came in at nearly 4000 PPM, the other at 1750 PPM. But the supplier’s recommendation for drying time and temperature were the same.”

Haynie, explained, “The difference between this product and other similar moisture analysis products currently being sold is that the DryerGenie will detect moisture in resin before it gets to the dryer, whereas most products are measuring pellet moisture at the end of the drying process. Measurements at the end of the process are simply done too late in the process to make adjustments that could save processing time and energy and avoid making bad products. This product is priced at less than $3000.00, making it feasible to use on the shop floor versus in a lab setting.”

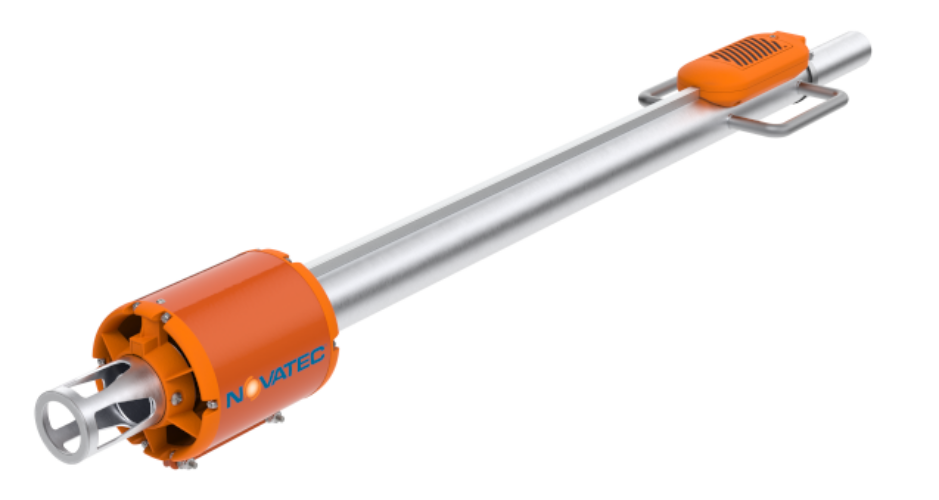

Sensor’s in Novatec’s DryerGenie Pickup Lance measure initial and real-time moisture levels and communicate changes to dryer setpoints.