Menu

In other words…How Do Systems Work?

The most simple step towards automation is to employ a vacuum loader and though it is more efficient than the bucket brigade – having a plant full of them is very inefficient Vacuum Loader Drawbacks compared to an automated plastics conveying system. Still, we will cover the advantages and drawbacks of this simple device before we talk about larger systems.

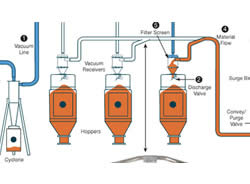

Larger systems all operate using the same basic principle. See Basic Central System Operaton. They use one or more strong vacuum pumps to create an airstream in which resin can be transferred from one or more sources to one or more destinations. There are several types of systems and multiple variations on those.

Ask the Expert