How to Prevent Vacuum Pump Failures That Cause Resin Conveying Downtime

A Predictive Maintenance Guide for Plastics Processors

Introduction: When the Material Stops Moving

Every plastics processor has experienced it. Production is running smoothly—material flowing from silos to hoppers, molding machines cycling consistently, parts coming off the line exactly as they should. Then, without warning, a vacuum pump fails. Material stops moving. Hoppers run empty. Production lines go dark.

The frustrating part? There were no alarms, no warnings, no gradual decline in performance that might have prompted preventive action. The pump just stopped.

But here’s what most processors don’t realize: those “unexpected” failures are rarely as sudden as they seem. Vacuum pumps give off warning signs for days or even weeks before they fail—signs that would be obvious if anyone could see them. The problem isn’t that pumps fail without warning. The problem is that most facilities operate pumps completely blind, with no visibility into equipment condition until it’s too late.

In this guide, we’ll explore why vacuum pumps fail, what resin conveying downtime really costs, and how modern monitoring technology can help you prevent failures before they stop production.

Why Vacuum Pumps Fail "Without Warning"

Walk into most pump rooms in plastics processing facilities and you’ll find equipment operating in complete isolation. Unlike injection molding machines that display dozens of parameters, or dryers that alert operators to filter changes, traditional vacuum pumps are essentially “on/off” devices. They either run or they don’t—with no intelligence to report on their condition.

This creates a fundamental blind spot. A pump might be struggling with dirty oil, worn bearings, or restricted filters for weeks before anyone notices. And by the time problems become obvious during routine rounds—unusual noise, excessive heat, visible vibration—the failure is typically imminent.

The Warning Signs You Can’t See

Inside every vacuum pump, several predictable failure modes develop over time:

- Bearing wear accumulates gradually and invisibly. For weeks or months, microscopic wear has no noticeable effect on performance. But bearing degradation follows a predictable curve: slow and steady, then a sharp acceleration as damaged bearings create more friction, generate more heat, and cause even faster deterioration. By the time bearing noise becomes audible, you’re often days away from catastrophic failure.

- Oil quality degrades as it breaks down from heat and becomes contaminated with particles from normal wear. Degraded oil provides less lubrication and cooling, forcing the pump to work harder and accelerating wear on all internal components. Eventually, degraded oil leads to overheating, seal failure, and seized components—but this happens gradually, invisibly, until the day the pump fails.

- Filters restrict airflow as they accumulate dust and debris. As restriction increases, the pump must pull harder to move the same amount of material. This increased load affects everything downstream—higher operating temperatures, increased vibration, faster oil degradation. A pump can compensate for restricted airflow for a surprisingly long time, masking the problem until multiple stress factors converge.

- Vibration patterns shift as components wear or conditions change. Every pump has a normal vibration signature that indicates healthy operation. As bearings wear, alignment shifts, or imbalance develops, this signature changes—creating a diagnostic trail that leads to failure, but only if someone is watching for it.

All of these warning signs occur in remote pump rooms where operators rarely venture. Without monitoring, early indicators of developing problems go completely undetected until the pump fails and production stops.

All of these warning signs occur in remote pump rooms where operators rarely venture. Without monitoring, early indicators of developing problems go completely undetected until the pump fails and production stops.

The True Cost of Resin Conveying Downtime

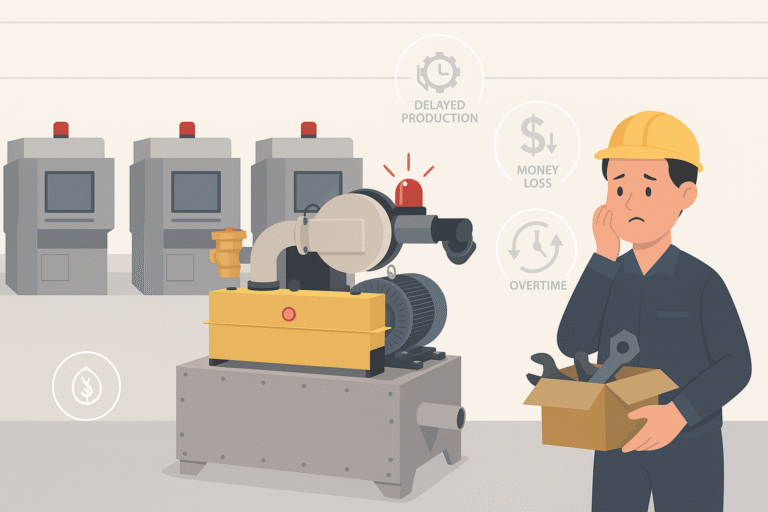

When a vacuum pump fails unexpectedly, the immediate impact is obvious: production stops. But the total cost of resin conveying downtime extends far beyond the hours spent waiting for repairs.

Direct Production Losses

In a typical facility, a single vacuum pump might supply material to multiple molding machines. When that pump fails, every machine it serves goes down simultaneously. If you’re running four machines at 60-second cycle times with $5 margin per part, that’s $1,200 per hour in lost profit—before accounting for any other costs. And the losses multiply if the failure occurs during high-value production runs or when just-in-time delivery commitments are at stake.

Emergency Repair Premium

Unexpected failures force maintenance into the most expensive mode possible: emergency response. Parts that could have been ordered at standard pricing now require overnight shipping. Technicians who might have been scheduled during regular hours now command overtime rates. A bearing replacement that would cost $800 during planned maintenance might cost $2,500 as an emergency repair when you factor in expedited parts, overtime labor, and expedited delivery.

Cascade Effects

Resin conveying downtime doesn’t just affect the machines served by the failed pump—it creates ripple effects throughout your material handling system. Material in transit when the pump failed may need to be cleared from lines. Hoppers that ran empty must be refilled and purged to ensure material quality. In centralized systems, a single pump failure can disrupt material flow patterns across multiple production areas, forcing operators to reroute material or run machines from backup hoppers—both of which create their own inefficiencies and quality risks.

The Reactive Maintenance Trap

Perhaps the most insidious cost is how reactive pump maintenance creates ongoing inefficiency. Without data about actual pump condition, most facilities adopt one of two problematic approaches:

- Calendar-based over-maintenance—changing oil and filters more frequently than necessary “just to be safe”—wastes maintenance resources while providing false confidence. (After all, a pump with fresh oil can still fail if bearings are worn.)

- Run-to-failure maintenance—accepting that pumps will eventually fail and simply dealing with it—trades lower preventive costs for much higher reactive repair costs and production losses.

Both approaches are inefficient because they’re based on guesswork rather than actual equipment condition. And both lead to unnecessary resin conveying downtime.

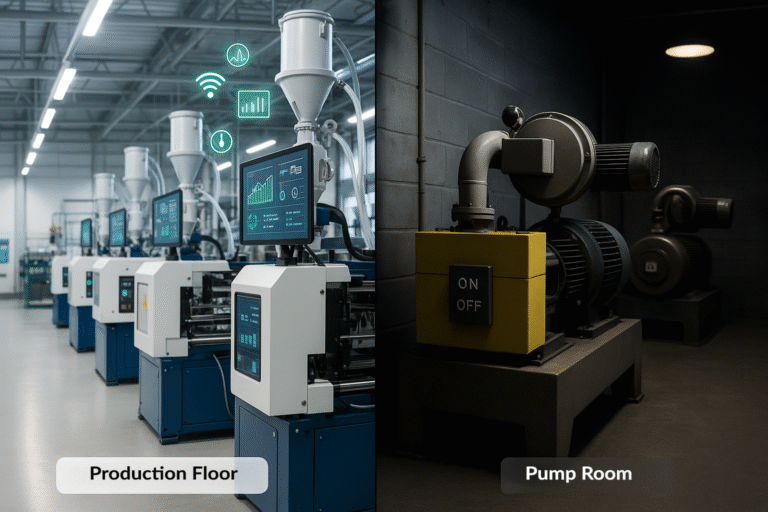

The Industry Paradox: We Monitor Everything Except What Matters Most

Here’s the contradiction that exists in nearly every plastics processing facility: walk through the production floor and you’ll find sophisticated monitoring everywhere. Injection molding machines display dozens of parameters in real-time—injection pressures, melt temperatures, cycle times, cushion positions. Resin dryers alert operators to filter changes, monitor dew points, and track temperature profiles. Even auxiliary equipment like chillers, TCUs, and material handling systems provide performance data and maintenance alerts.

This predictive monitoring has become a more widely adopted operating practice across the industry because it works. By catching problems early, facilities avoid the costly emergency repairs and unexpected downtime that plagued operations for decades. Maintenance teams have embraced this technology because it transforms their work from constant crisis response into planned, efficient operations.

Yet venture into the pump room—where the equipment that makes your entire material handling system possible lives—and you’ll find those same facilities running pumps completely blind. No monitoring. No alerts. No visibility into equipment condition. These pumps, which may represent tens of thousands of dollars in investment and are absolutely critical to production, operate with the same level of intelligence they had thirty years ago: on or off.

This blind spot persisted not because anyone forgot about pumps, but because the technology to monitor them cost-effectively simply didn’t exist. Years ago, vibration sensors and oil quality monitors cost thousands of dollars. Outfitting auxiliary equipment like pumps wasn’t practical.

But the landscape has fundamentally changed. Advances in sensors, processing power, and A.I. have made monitoring affordable and accessible. Sensors that once cost thousands now cost hundreds. Edge computing can now run sophisticated analysis locally without cloud connectivity. The monitoring technology that was once reserved for critical production equipment is now practical for the pumps that feed your entire operation.

For the first time, processors can bring the same predictive capabilities they rely on everywhere else to the equipment that matters most—without prohibitive costs or complex integration.

How Monitoring Prevents Failures

The evolution from reactive to predictive pump maintenance requires the same thing that transformed maintenance for molding machines and dryers: visibility into equipment condition before problems become failures. Modern monitoring systems track the parameters that indicate developing issues—vibration, oil quality, temperature, filter restriction—and alert maintenance teams when intervention is needed.

This approach transforms maintenance from guesswork into precision. Instead of changing oil on a calendar schedule regardless of condition, you change it when monitoring data shows degradation. Instead of waiting for bearings to fail catastrophically, you detect wear early and replace them during planned downtime. Instead of discovering filter restriction after it causes problems, you catch it when differential pressure first begins to rise.

The Predictive Advantage

Monitoring-based maintenance offers several critical advantages:

- Problems are caught early when repairs are simple and inexpensive

- Maintenance occurs during planned downtime rather than emergency situations

- Emergency failures are minimized, protecting production schedules

- Equipment life is extended because problems are addressed before causing secondary damage

- Maintenance resources are allocated based on actual need rather than assumption

The key is having accurate, continuous data about pump condition—not just snapshots during scheduled rounds, but 24/7 monitoring that catches developing issues regardless of when they occur.

Beyond Single Parameters

The most effective monitoring doesn’t just track individual parameters in isolation—it analyzes patterns and relationships. Rising vibration combined with increasing temperature might indicate bearing problems. Declining vacuum levels with normal vibration could suggest filter restriction or seal wear. By understanding how parameters interact, monitoring systems can identify specific issues and provide guidance on appropriate maintenance response.

For facilities looking to implement comprehensive material handling monitoring across pumps, conveying lines, and dryers, our Ultimate Guide to Conveying Monitoring for Plastics Processors provides detailed information about system-wide strategies and how different monitoring technologies work together to optimize performance and reliability.

Bringing Pumps Into the Modern Age

At Novatec, we’ve spent decades understanding the unique challenges that plastics processors face with material handling systems. We know that when a pump fails unexpectedly, it doesn’t just mean a maintenance call—it means stopped production, missed deliveries, and the kind of pressure that keeps plant managers awake at night.

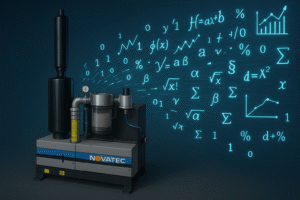

That’s why we developed PumpSense: the industry’s first and only comprehensive vacuum pump monitoring solution designed specifically for material handling applications in plastics processing. While predictive monitoring has been standard for molding machines for years, vacuum pumps have been neglected—until now.

Why Novatec Is Uniquely Positioned

We didn’t just decide to add sensors to pumps and call it a day. PumpSense represents decades of experience in material handling, combined with deep understanding of what plastics processors actually need. We know the consequences of resin conveying downtime. We understand the challenges of maintaining equipment in remote pump rooms. And we recognize that your equipment data is proprietary and should stay under your control.

Pre-Trained with Decades of Pump Health Data

One of the biggest challenges with predictive monitoring isn’t installing sensors—it’s teaching the system what to look for. Generic platforms require you to train them manually: run pumps in perfect condition, run them in degraded states, and hope the software learns the difference.

PumpSense eliminates that burden. We’ve been collecting and analyzing pump health data for more than a decade, building one of the most comprehensive datasets in the industry. Every vibration signature, every vacuum drop, every failure mode—it’s already in the system.

That means PumpSense arrives pre-trained. Right out of the box, it knows the difference between healthy operation and a pump heading for trouble. Its predictive algorithms are backed by years of real-world pump behavior across hundreds of thousands of hours of operation.

No other company in the plastics processing industry offers dedicated pump health monitoring for material handling applications. This isn’t an afterthought or a generic industrial sensor package—it’s a purpose-built solution informed by years of experience with the specific demands and failure modes of vacuum pumps in plastics processing environments.

On-Premise Intelligence, Not Cloud Dependency

Unlike generic monitoring systems that require cloud connectivity and subscription fees, PumpSense processes and stores all data locally on-site. This approach provides critical advantages:

- Your proprietary equipment and production data never leaves your facility

- Monitoring continues uninterrupted even if internet connectivity is lost

- No recurring subscription fees for cloud storage or processing

- You maintain complete control over your maintenance information

- Data access speeds aren’t dependent on internet bandwidth

We believe your equipment data should stay where it belongs—in your facility, under your control. That’s not just philosophy; it’s how PumpSense is designed from the ground up.

This preference for on-premise solutions isn’t unique to us—it reflects what the industry wants. Data suggests that plastics processors favor on-premise monitoring over cloud-based alternatives by roughly 3-to-1, particularly for critical production equipment. For processors who value data security and long-term cost predictability, on-premise monitoring has become the preferred choice.

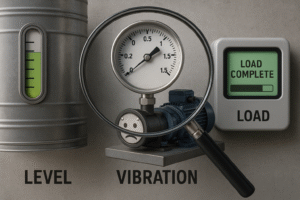

What PumpSense Monitors

PumpSense tracks the parameters that matter most for vacuum pump health in material handling applications:

- Vibration analysis using industrial-grade accelerometers that detect bearing wear, misalignment, and mechanical issues weeks before they become critical

- Oil quality monitoring that tracks contamination, viscosity changes, and degradation in real-time

- Temperature monitoring at critical points to identify overheating, excessive load, or cooling problems

- Filter differential pressure to catch restriction before it affects pump performance

- Runtime and cycle data to track utilization patterns and predict maintenance windows

Choose Your Visibility Level

We understand that different facilities have different needs, existing systems, and operational preferences. That’s why PumpSense offers multiple implementation options—all while keeping your data on-premise without cloud dependency or subscription fees.

Standalone Mode with Local Indicators Every PumpSense unit includes built-in visual indicators—green, yellow, and red status lights—that provide immediate feedback about pump condition. This works perfectly for facilities where maintenance staff regularly check pump rooms and want instant visual confirmation of equipment status. No network required, no software to install—just clear, actionable alerts right on the pump.

Software Monitoring via Master Data Hub For facilities wanting centralized visibility, our Master Data Hub provides comprehensive monitoring capabilities. This compact, on-premise device:

- Automatically discovers all PumpSense-equipped pumps on your network

- Provides web-based dashboards accessible from any computer in your facility

- Stores historical data locally for trending and analysis

- Handles all your facility’s PumpSense-equipped pumps from a single hub

- Generates maintenance reports and performance summaries

- All data remains on-premise with no external connectivity required

Integration with Existing Novatec Systems Already using Novatec equipment controllers like our FTS-2 touchscreen controller for mid-sized operations or FX3 central control system (which acts like a mini-SCADA for plant-wide monitoring)? PumpSense integrates seamlessly, adding pump health monitoring alongside your existing dryer, conveying, and system management data. This creates unified visibility across your entire material handling operation—all controlled from the systems you already use.

Enterprise System Integration For facilities with existing SCADA, MES, or other facility management platforms, PumpSense can export data in standard formats for seamless integration. This allows pump health data to appear alongside other critical equipment parameters in your existing operator interfaces and maintenance management systems—without forcing you to adopt new platforms or change established workflows.

The key advantage: regardless of which implementation approach you choose, your data stays on-premise, you pay no subscription fees, and you maintain complete control over your monitoring information.

Easy Implementation

Getting started with PumpSense is straightforward. PumpSense is available as an affordable add-on to any Novatec pump and comes standard on our new line of ultra-quiet Infinity Series pumps. Every PumpSense-equipped pump includes built-in LED indicators for immediate visual status.

For full predictive capabilities across your facility, add a single Master Data Hub that collects data from all your PumpSense-enabled pumps. No subscription fees, no per-pump licensing costs. Just one hub for your entire facility.

From there, you choose how you want to access your pump health data: through the Master Data Hub’s browser interface, integrated with Novatec controllers (FTS-2 for smaller operations, FX3 for enterprise-level monitoring), or exported to your facility’s SCADA or MES systems.

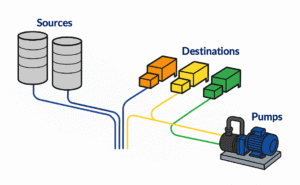

Beyond Pumps: Complete Vacuum Conveying System Monitoring

While we’re focused here on preventing pump failures, PumpSense is designed to integrate seamlessly with complete vacuum conveying system monitoring. Novatec’s central controllers—the FTS-2 for small to mid-sized operations and the FX3 for larger, more complex facilities—provide comprehensive monitoring of sources (silos, surge bins, gaylords) and destinations (receivers feeding presses, extruders, dryers) alongside pump health data.

When you integrate PumpSense with Novatec’s central controllers, you gain a unified view of your entire conveying system in one interface. You’re not managing separate monitoring platforms—pump health appears alongside material levels, load scheduling, and system utilization. This integrated approach helps facilities understand relationships between different system components: how pump performance affects material delivery, how system demand impacts pump stress, and how filter conditions correlate with overall conveying efficiency.

For more information about comprehensive material handling monitoring strategies and how pump health fits into overall system performance, see our Ultimate Guide to Conveying Monitoring for Plastics Processors.

Ready to Prevent Your Next Failure?

Unexpected vacuum pump failures and the resin conveying downtime they cause don’t have to be inevitable. With the right monitoring technology, warning signs become visible weeks or months before catastrophic failure occurs—providing ample time for planned maintenance during scheduled downtime rather than emergency repairs during production.

If you’re ready to move beyond reactive pump maintenance and start preventing failures before they stop production, we’d like to help. Give us a holler, or reach out on the form below, to discuss your specific equipment, applications, and challenges. We’ll help you identify where PumpSense monitoring can deliver the greatest impact and outline what implementation would look like in your facility.

No sales pitch. No pressure. Just a practical conversation about what’s possible when you can see what’s happening inside your pumps before problems become failures.

Because in plastics processing, preventing resin conveying downtime isn’t just about avoiding costs—it’s about maintaining the consistent, reliable production that your customers depend on.

Submit A Question: Conveying

Ask the Expert