How Loud Conveying Systems Can Cost You— and What to Do About It

If your vacuum pump is loud enough to interrupt conversations on the production floor, it might be doing more than just annoying your team. It might be putting your entire operation at risk.

Excessive vacuum pump noise isn’t just a comfort issue anymore. It’s an OSHA compliance problem, a potential workers’ compensation liability, and a source of mounting legal risk in plastics processing plants across the country.

And most processors don’t even realize they’re vulnerable—until the lawsuits start rolling in.

The Hidden Danger of Vacuum Pump Noise

Vacuum pumps move material by moving air—and they do it loudly. In fact, many conventional pumps easily cross OSHA’s noise exposure thresholds — especially as they age or operate in echo- prone environments — triggering regulatory requirements and expensive mitigation steps.

Here’s the breakdown:

- 85 dB(A) – over an 8-hour shift? You’re legally required to implement a hearing conservation program, including annual hearing tests.

- 90 dB(A) Hearing protection is mandatory.

- Over 115 dB(A)? Immediate protection is required—unprotected exposure is illegal.

And if your pumps are running above these thresholds—even occasionally—you’re at risk of OSHA fines, forced retrofits, and workers’ comp claims.

Hearing Loss Lawsuits Are on the Rise

It’s not just OSHA you need to worry about. Hearing loss is a compensable injury in every state—and personal injury lawyers know it.

You’ve probably seen the ads:

“If you’ve worked in a loud factory and suffer from hearing loss, you may be entitled to compensation…”

That ad is targeting you. Or your employee. Or your insurance provider.

Even if the real cause of hearing loss was a lifetime of rock concerts or blasting headphones, if your pump is loud and lacks proper documentation or mitigation, your operation is an easy target.

The Logistics You Don’t See… Until They Cost You

Loud pumps don’t just bring legal risks—they reshape how your entire plant is laid out.

Many processors have had to banish their vacuum pump to a remote soundproof room just to avoid compliance issues. But that fix comes with real costs:

- Longer conveying lines = more pump stress, more material wear, higher energy usage, and increased maintenance.

- Bigger pumps than you really need, just to move material across longer distances.

- Harder maintenance access, since the pump is no longer on the production floor.

Think of it like putting a noisy engine in a soundproof basement and running pipes all through your house—just to keep the peace upstairs. It’s complicated, expensive… and unnecessary if you had a quieter engine to begin with.

Smarter, Quieter Solutions — No Sound Room Required

Look, this isn’t a hypothetical problem. At Novatec, we see this stuff every day — processors wrestling with noisy pumps, worried about OSHA compliance, trying to avoid costly sound rooms or unnecessary remote installs.

That’s exactly why we’ve developed three different vacuum pump solutions — each designed to solve the noise problem, safeguard you from liability, and (maybe best of all) let you put your pump right where it belongs — on the production floor.

No sound room. No extra-long conveying lines. No overpowered pump just to move material from the back corner of the plant.

Just smart, quiet, right-sized solutions — depending on your setup, your budget, and how much noise reduction you’re really after.

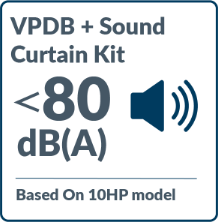

Good: VPDB Series Pumps + Sound Curtain Kit

Reliable Performance, Budget-Friendly Noise Control

If you’re running a Novatec VPDB vacuum pump already, adding a sound curtain kit is a fast and affordable way that will reduce noise by an impressive ~10 dB(A), when installed according to recommended guidelines. Enclosures are available for both single and dual stack configurations, so you’re covered no matter how your VPDB system is set up.

- No sound room needed

- Easy to retrofit or order bundled

- Effective sound reduction

Trade-offs: The curtain does add some bulk around the pump, can retain heat, and limits visibility of pump and health indicators. Still, it’s a great first step for plants that already have a VPDB and need a quiet, economical upgrade.

But if you’re purchasing a new pump and looking for a quiet solution from the start, Novatec’s SVP Series is actually the more economical choice. That’s because by the time you factor in the cost of a VPDB plus a sound curtain kit, the SVP delivers built-in noise control at a lower total cost—and without the added bulk.

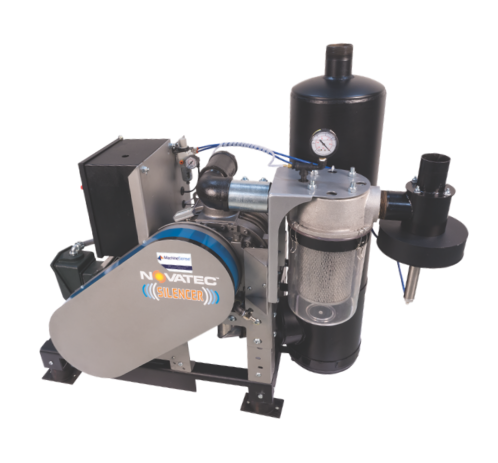

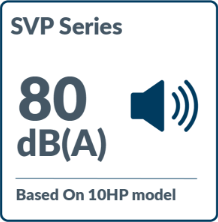

Better: SVP Series ‘Silencer’ Pumps

Designed to Be Quiet from the Start

Why add a workaround when you can just start with a quiet pump?

The SVP Series takes everything great about the VPDB and wraps it in a purpose-built, sound- reducing design that’s

OSHA-compliant noise levels: 78–80 dB(A)

No curtain required

Better aesthetics, less hassle, same vacuum performance

Drawback: It’s currently only available in 3, 5, and 10 HP sizes. If one of those fits your operation, it’s a fantastic solution. But for larger systems—or those that need future flexibility—there’s an even more advanced option.

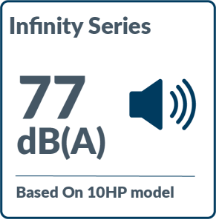

Best: Infinity Series Ultra-Quiet ‘Smart’ Pumps

The Quietest—and Smartest—Vacuum Pump on the Market

If you’re looking for the ultimate solution to pump noise, this is it. The Infinity Series is built around an EV-inspired Direct Drive Magnetic Motor eliminating belts, reducing vibration, and delivering a level of quiet most processors didn’t think was possible in a PD pump.

- Sound levels below 80 dB(A) No sound room needed

- Full horsepower range: 3, 5,

- 7.5, 10, & 15 HP

- Smart monitoring and health status indicators (standard)

- Ultra-efficient motor design delivers breakthrough energy savings compared to traditional PD pumps

- Optional auto-clearing blockage detection when paired with Novatec’s FX3 Controller

It’s not just quiet—it changes your entire conveying setup.

- Shorten your conveying lines

- Use a smaller, more efficient pump

- Reduce installation costs

- Avoid expensive retrofits or acoustic chambers

And with real-time monitoring, built-in alerts, and fewer mechanical parts to wear down, it’s built to outlast and outperform traditional vacuum systems.

Not sure which pump is right for your plant? Check out our Ultimate Guide to Vacuum Pumps for Plastics Processors for a detailed breakdown of how each type works—and how to choose the best fit.

The Bottom Line: Don’t Let Noise Run Your Plant

If you’re making decisions around vacuum pumps based on how to control the noise after the fact, you’re already spending more than you should.

By choosing a quiet vacuum pump solution from the start, you can avoid:

- OSHA hearing conservation programs

- Workers’ comp claims

- Sound room construction and maintenance

- Oversized pumps to compensate for long lines

Instead, you get a smoother, quieter, and smarter conveying system—and the peace of mind that you’re doing it right.

Need help figuring out what’s best for your setup?

Give our conveying experts a holler using the form below. No pressure, no sales pitch—just a conversation about what’s right for your plant.

Let’s quiet things down, the smart way!

Ask the Experts!

Ask the Expert