As a plastics processor, selecting the right resin drying system is crucial to ensuring efficient production and high-quality finished products. While press-side resin dryers have been the go-to option for many processors with small-scale operations, more and more manufacturers are transitioning to centralized drying systems to meet their production requirements.

In this article, we’ll explore the differences between press-side and central resin drying systems, the benefits of each approach, and ultimately, why transitioning to a central plastic resin drying system might be the smart choice, especially if you’re looking to increase production, efficiency, and profitability.

Press-Side Resin Drying: When Is It The Right Choice?

Press-side or press-mounted resin dryers are commonly used in facilities with fewer than 10 process machines and low throughputs (between 25 – 100 lb/hr). This approach is ideal for processors who run the same material on the same machine daily, with minimal material changes.

With press-side drying, there is a vacuum loader at each drying hopper, and a bulk box or drum of resin is the source of material. While this approach is ideal for many processors, it can present some disadvantages for others. For example, this arrangement requires constant forklift traffic and room to deliver material to the presses, which can lead to contamination and wasted materials.

Portable dry/convey units are an interim solution for processors looking to upgrade their drying systems without making the leap to central drying. These units have throughputs of up to 200 lb./hr. and are typically mounted on a cart with a drying hopper, a loader or receiver to supply resin to the drying hopper, and a machine-mount loader or receiver to deliver material to the machine throat up to 200pph.

However, the need for bulk boxes and forklifts remains, which can cause confusion on the production floor and result in materials being left in the bulk bins and/or contaminated and wasted

Central Plastic Resin Drying: What Is a Centralized System?

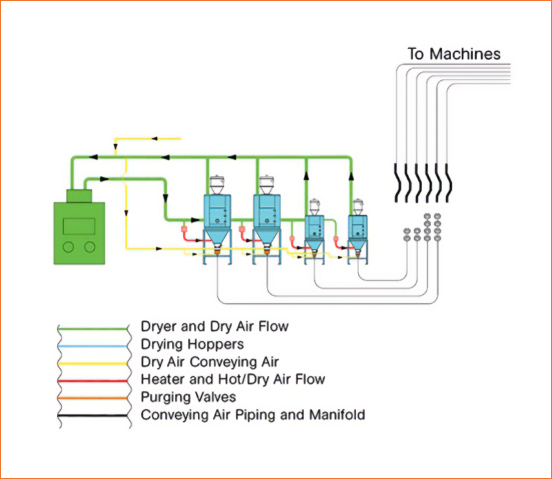

Centralized resin drying systems provide a single dryer that can provide -40°dew point air to multiple material hoppers of different sizes. An adjustable heater and blower are mounted on each hopper so the heat and air flow can be adjusted to the material in that hopper. This arrangement allows for custom drying of multiple materials from a single central dryer that is sized to match the requirements of the bank of hoppers.

Central plastic pellet dryers are available with throughputs from <200 lb/hr through 5,000 lb/hr, which meet a wide range of processor needs. Processors often have more than one central dryer – each serving a bank of hoppers with a back-up central dryer for times when a dryer may be taken offline for maintenance.

Are You a Good Candidate for Central Drying/Conveying?

If you have dryers on 10 or more machines, a single material that requires drying at multiple machines, frequent material changes on your machines, or use more material types than you have machines, then central drying is most likely the best option for you.

Additionally, centralized resin drying offers a notable advantage: the ability to pre-dry the next resin, thus curtailing non-productive time. By establishing a network that interconnects various processing machines with a centralized drying unit, processors can seamlessly sustain production while simultaneously preparing the subsequent resin for deployment.

This eliminates the waiting game, slashes changeover durations, and ensures optimal drying conditions for different resin variants. The outcome? A substantial boost in productivity, minimized downtime, and a surge in operational efficiency.

Centralized resin drying systems also provide flexibility to serve the needs of your customers, reduce operating costs, and improve worker safety. If you have a justin-time objective to reduce inventory, need to reduce operating costs, or want to expand without sufficient space, then a centralized resin drying system is the perfect solution for your operation.

Ask the Expert